U.S. Army Engine Plant

Sediment Remediation Project Technical Support

Over the course of its history, the Stratford Army Engine Plant (SAEP) was site of significant developments in U.S. aviation and defense technology. Originally built in 1929 as Sikorsky Aero Engineering Corporation’s manufacturing facility, the plant occupied a 124-acre tract, included 49 industrial buildings and an earthen causeway extending into the Housatonic River mudflats. The manufacture of aircraft and engines at the SAEP facility involved general metal working, plating, metal finishing, and other processes.

At the request of the U.S. Army Corps of Engineers, Lally Consulting LLC conducted a 3rd Party evaluation of the SAEP site to provide recommendations of appropriate state-of-the-art dredging technologies and approaches for the environmental restoration at several locations on site. The project involves the removal of contaminated sediment over 58 acres in the tidal flats as well as upland areas. Lally developed a Dredging Alternatives report which provides analyses of the proposed remediation plan, sediment characteristics, bathymetry, water levels, shoreline structures and hydrodynamic conditions, based on available data. Appropriate dredge and dredged material management technology alternatives, as well as key performance considerations including dredgeability, production, accuracy, resuspension and residuals, and engineering controls were put forward by Lally for consideration during the remedial design phase. The report provided specifications and estimated performance characteristics for specialized precision mechanical, swinging ladder hydraulic cutterhead, and hybrid hydraulic/mechanical dredge alternatives, the preferred of which will be determined based on dredged material disposal, logistical constraints, and additional data collection and analyses to be conducted by the A/E Contractor and USACE.

Site History

The Stratford Army Engine Plant has changed ownership and names several times, including serving as a primary production facility at different periods for Sikorsky seaplanes and helicopters. In the early 1930s, the primary mode of long-distance air travel over oceans was in sea planes or “flying boats”, due to the ease of constructing docking facilities on shore without having to construct runways, and the possibility of malfunction forcing a sea landing. Several models of flying boats were built at the SAEP plant including the Sikorsky S-38 and S-42 “Baby Clipper”.

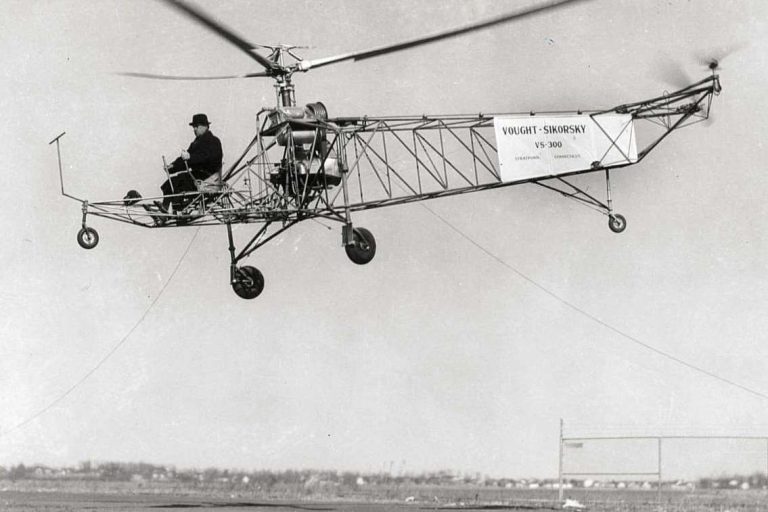

In 1938, due to the growing popularity of land-based aircraft, Sikorsky was merged with the Chance Vought Company by their parent United Aircraft. The Vought-Sikorsky company then built the VS-44 “Flying Boat” and Vought-Sikorsky OS2U Kingfisher, at the facility. The company separated into Vought Aircraft and Sikorsky Aircraft in January 1943. Igor Sikorsky, provided $250,000 for helicopter R&D by United Aircraft, developed the industry-defining VS-300.

The VS-300 was the first successful single lifting rotor helicopter in the United States and the first successful helicopter to use a single vertical-plane tail configuration for anti-torque.

With the outbreak of World War II, the Vought-Sikorsky Corsair high-speed fighter was developed and manufactured at SAEP. Vought also went on to build other important aircraft at the facility including the TBY Sea Wolf Dive Bomber, and XF5U. In its final chapter, SAEP supported the manufacture of engines for hydrofoils, hovercraft, helicopters, and, culminating in the 1980s, the Abrams XMI Main Battle Tank.

Services Provided

Site Investigation

Physical Conditions Evaluation

Hydrodynamic Conditions Analyses

Evaluate and Propose Alternative Dredge Technologies

Advise on Residuals and Water Quality Management

Public Meeting Presentation

Location

Connecticut, USA

Period

2017 – 2019