Contaminated Sediment Remediation

Award-winning Leadership

For more than a quarter century, Lally has quietly been leading some of the most important developments in the North American sediment remediation sector. Among these the engineering and implementation of precision dredging and capping technologies and methods; electronic positioning and monitoring systems; contour dredge prism and engineered cap design standards; site characterization technology and methods; integrated remediation and ecosystem restoration; and quality control, mapping products, data analytics and software tools to measure, benchmark and improve sediment remediation performance.

Lally’s innovations and education efforts are dedicated to achieving Maximum Remediation at Minimum Cost in order to do the greatest good for our clients and the environment.

Lally LLC provides remediation site owners, managers, regulators, contractors and consultants a broad range of sediment remediation services geared towards completing projects with superior cost efficiencies and minimized risk.

Since 2008 Lally LLC has completed the following sediment remediation project services;

- 24/7 Worldwide Support

- Project Management

- Sediment Remediation Expert

- Site Characterization

- Plan Formulation

- Setup of Confirmatory Sampling Program

- Sampling and Analysis Plans

- Establish Sample Spacing and Data Quality Objectives

- Remedial Engineering

- Dredging Engineering

- Dredging and Capping Plans and Specifications

- Plans and Prism Files

- Engineered Cap Design

- Cap Plans and Placement Files

- Precision Excavator Dredge Design

- Hybrid Mechanical – Hydraulic Dredge Design

- Hydraulic Dredge Design

- Hydraulic Capping Barge Design

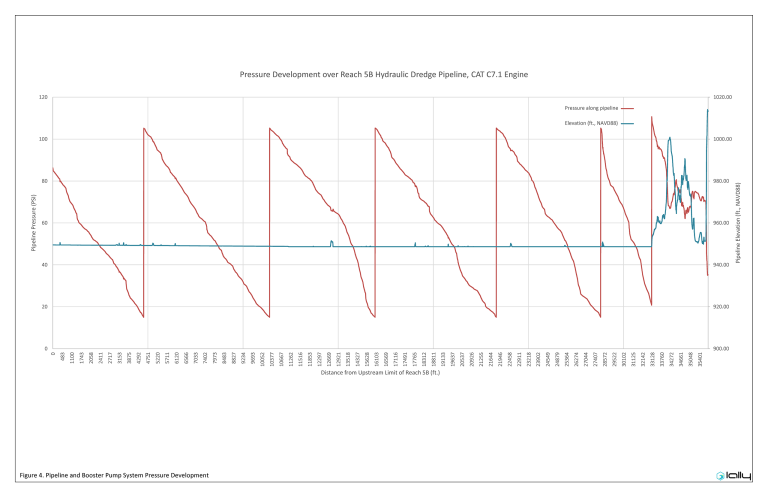

- Pump and Pipeline Layout

- Sediment and Soil Treatment Planning and Optimization

- Mechanical Dewatering Planning

- Volume and Mass Balance Estimates

- Production Estimates and Schedule Analysis

- Enhanced Natural Recovery Design

- Carbon Amendment Delivery and Measurement

- Dredged Material Disposal Planning and Management

- Nearshore Confined Disposal Facility Design

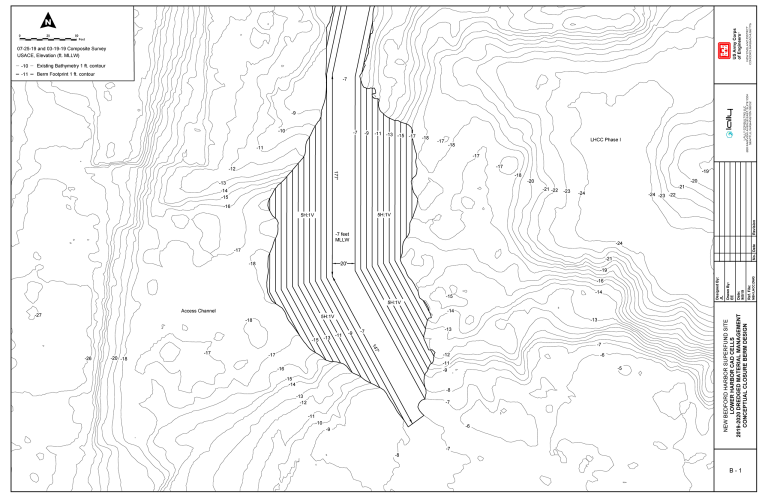

- Confined Aquatic Disposal (CAD) Cell Design

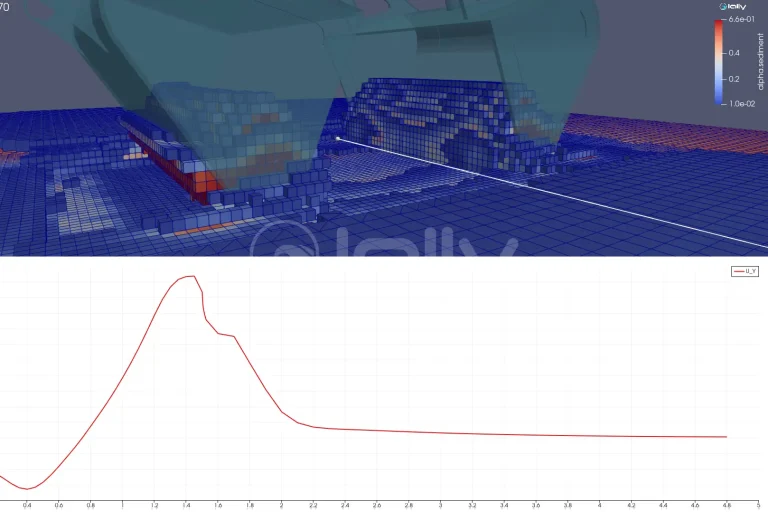

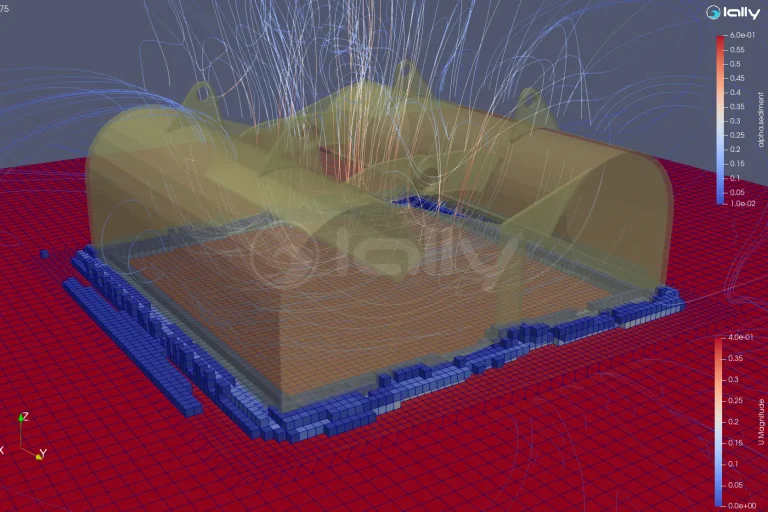

- FATE Modeling

- Procurement Support

- Cost Estimates

- Contractor Work Plan Development

- Training and Mentoring

- Project Startup

- Construction Oversight

- 3rd Party Technical Oversight

- Dredge and Cap Barge Positioning and Automation

- Precision Dredge Setup and Optimization

- Error Budgets

- Monitoring Systems

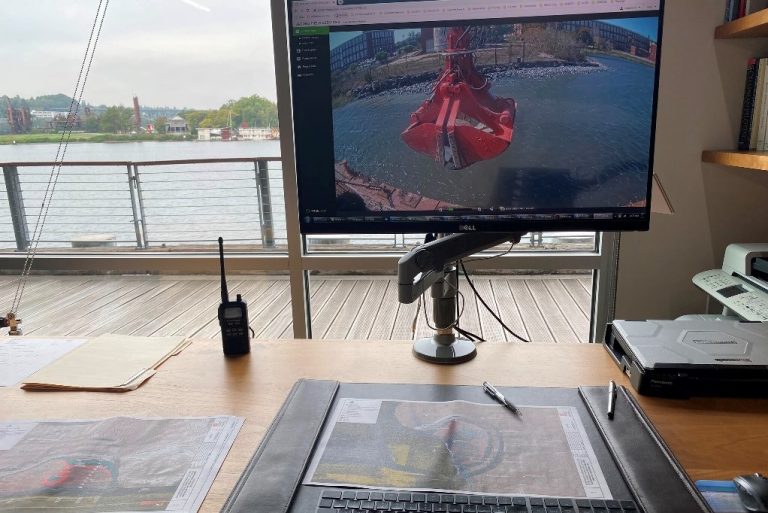

- Real-time Sediment Monitoring

- Flow and Slurry Density Measurement

- Project Performance Optimization

- Residuals Management

- GIS Data Management

- SWAC Management

- 2D and 3D Visualizations

- Diver-Engineer Inspections

- Pre-, Progress and Post-Dredge and Placement Surveys

- Dredging and Capping Performance Analyses

- Verification Plots and Data Analytics

- Acceptance Requests / Contract Management

- Quality Assurance / Quality Control

- Audits of Quality-affecting Activities

- Environmental Monitoring

- Quality of Life Monitoring

- Public Meetings Support and Infographics

- Owner / Agency Representation with Stakeholders

- Project Completion Reports and As-Builts

- Claims Resolution

- Expert Litigation Support

Lally LLC is a pacesetter in the Planning, Engineering and Operational Performance aspects of contaminated sediment remediation projects.

Lally has worked on over 1,000 dredging and marine construction projects involving hydraulic and mechanical dredge types, and served in leadership roles at numerous sediment remediation sites as consulting engineer and marine contractor. Important experience has been gained in the process, which Lally wants to share with clients, regulators and consultants in the ongoing pursuit of clean waterways and restored aquatic ecosystems.

Lally’s work and education efforts have helped advance the sediment remediation industry and been instrumental in the cleanup of numerous projects at some of the largest and most complex contaminated sediment sites in North America, including;

- Lower Duwamish Waterway Superfund Site

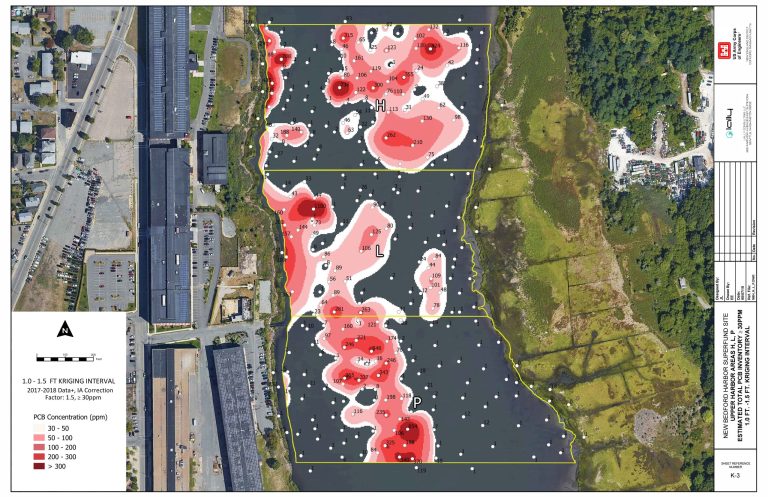

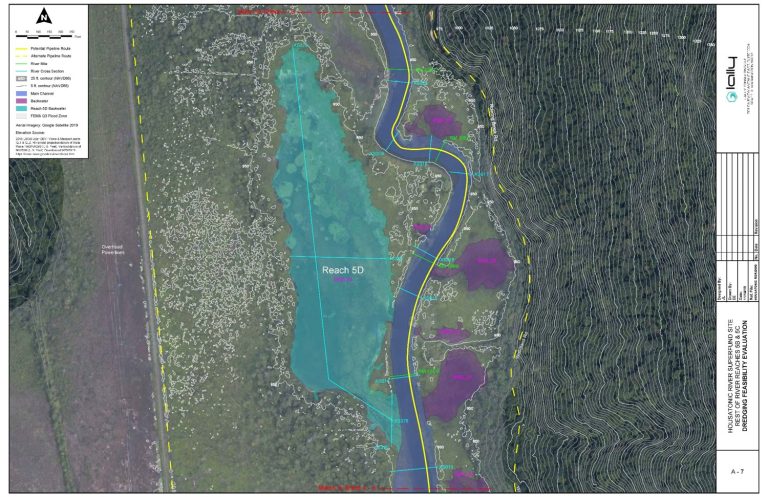

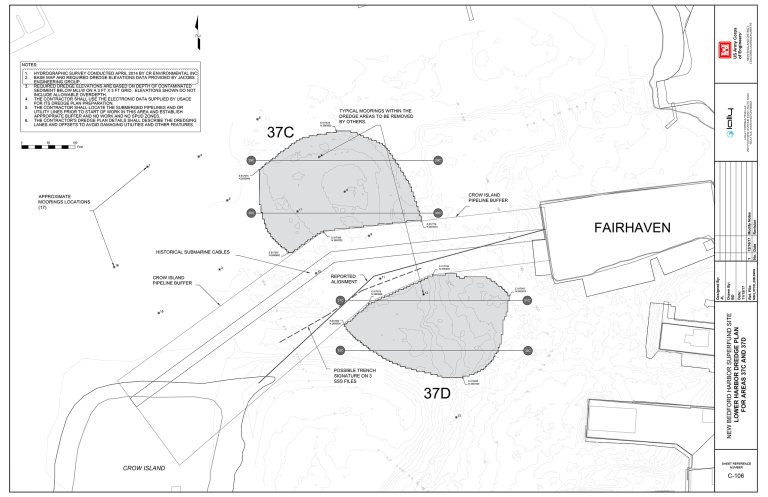

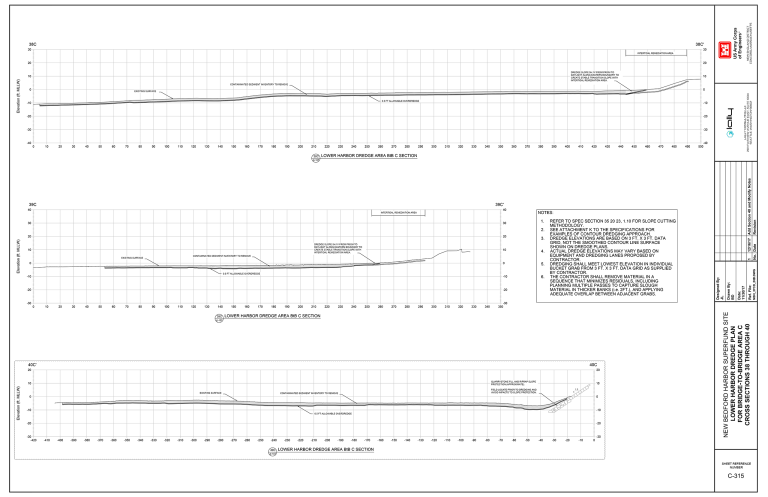

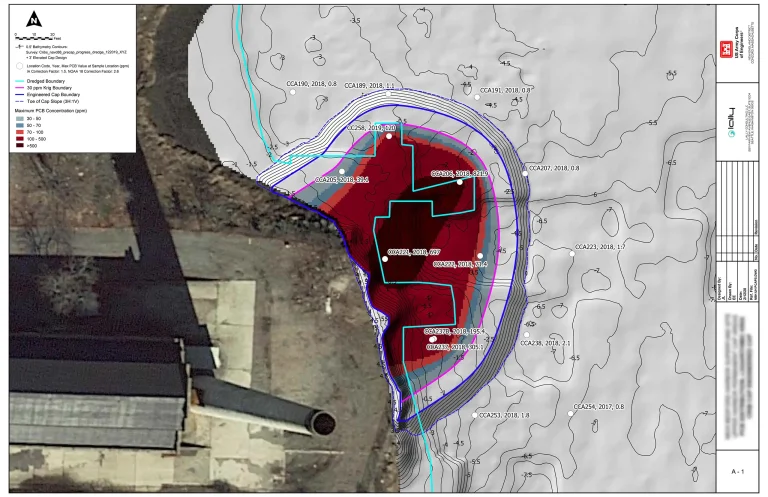

- New Bedford Harbor Superfund Site

- Hudson River Superfund Site

- Fox River Superfund Site

- Passaic River Superfund Site

- Portland Harbor Superfund Site

- Commencement Bay / Nearshore Tideflats Superfund Site

- Eagle Harbor Superfund Site

- Ward Cove Superfund Site

- Marathon, Peninsula Harbour Cleanup

- Gowanus Canal Superfund Site

- Newtown Creek Superfund Site

- Onondaga Lake Superfund Site

- Berry’s Creek Study Area Ventron/Velsicol Superfund Site

- and many other sites…

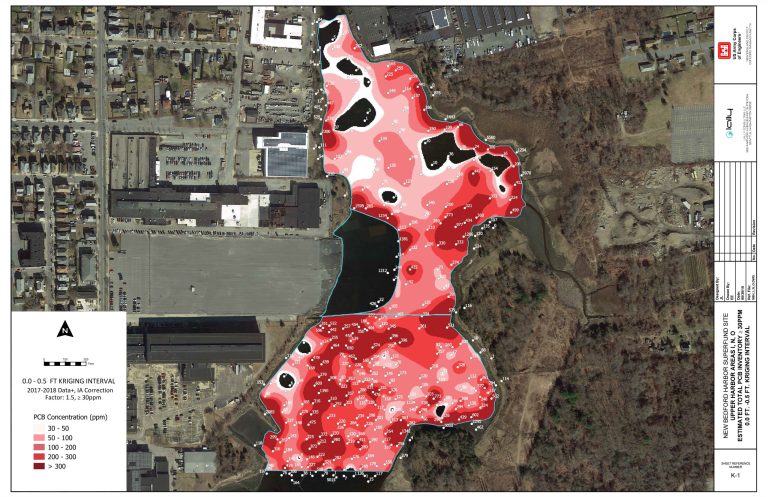

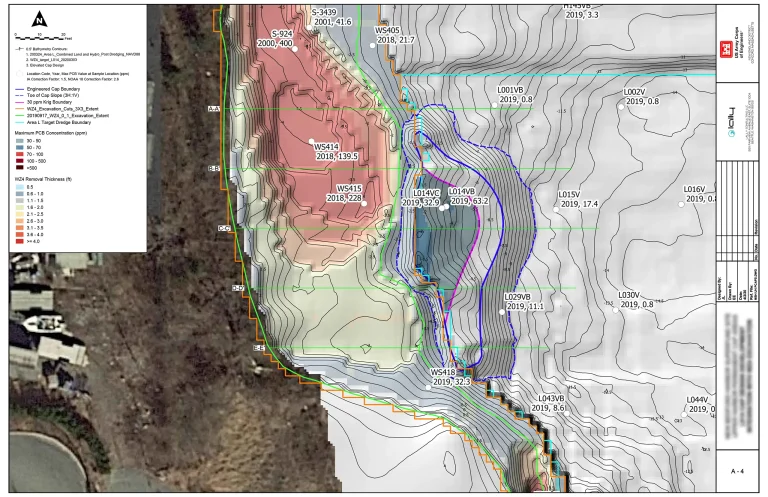

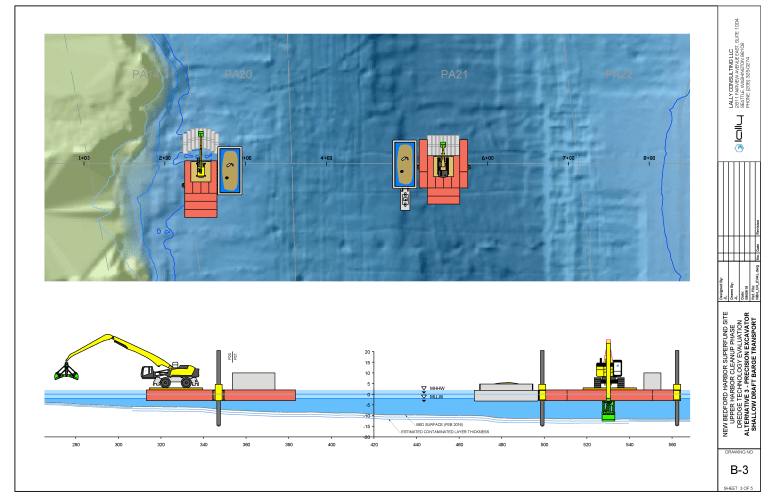

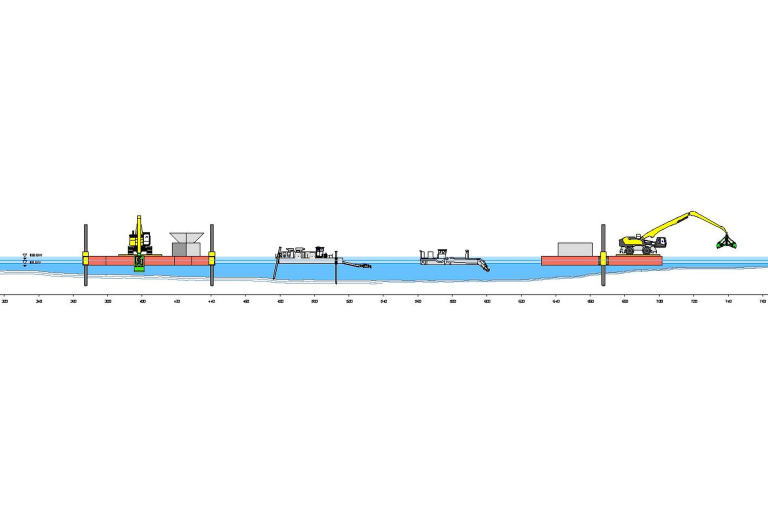

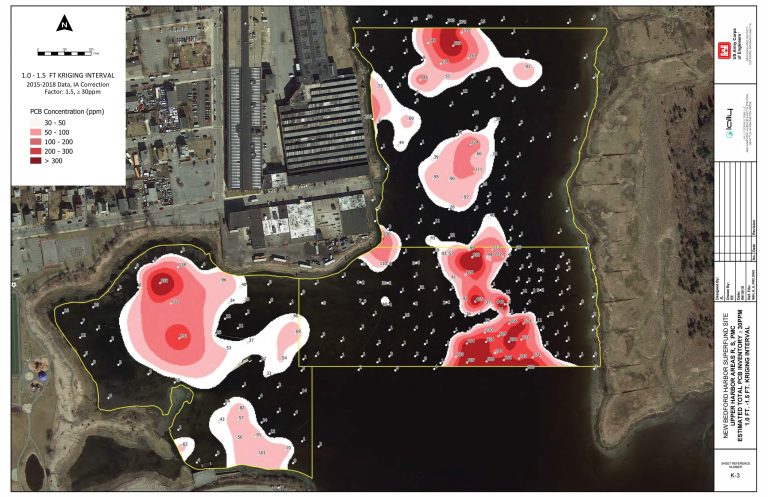

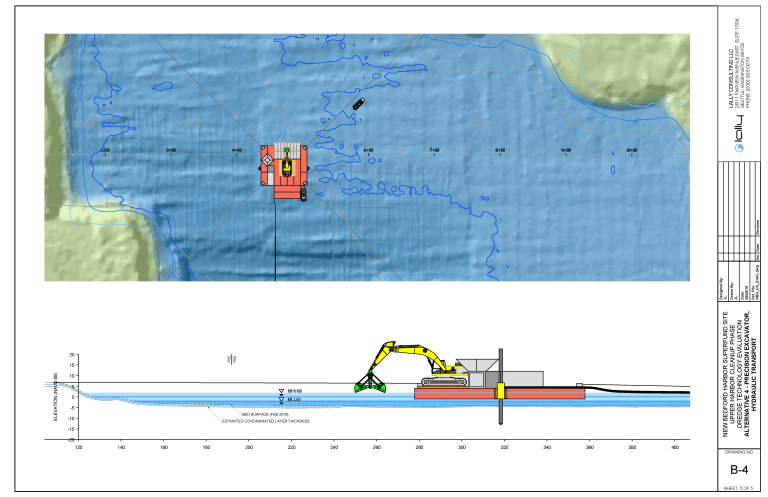

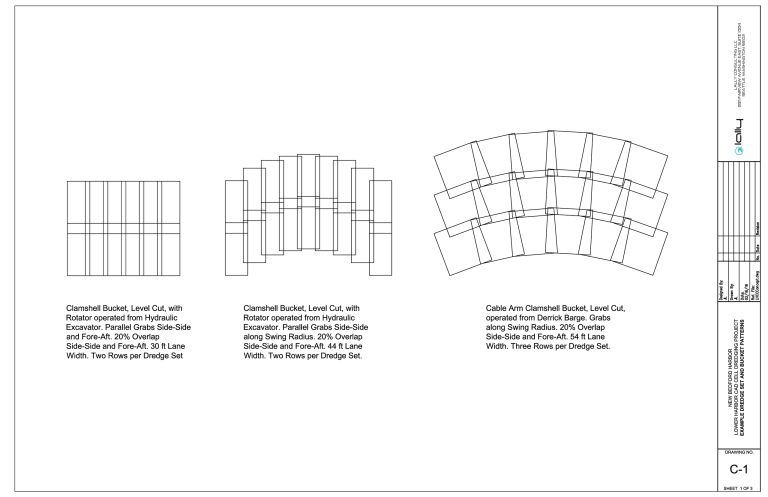

In the late 1990s, working as Marine Remediation Engineer helping plan large contaminated site remediations at New Bedford Harbor, MA, Hudson River, NY, Lower Duwamish Waterway, WA, and Commencement Bay, WA, Lally recognized that the marine equipment available for complex and costly sediment remediation projects in these regions were limited to derrick (crane) barges with wire-controlled clamshell buckets, and hydraulic cutterhead dredges. Both of these types of conventional dredge systems, even with ‘environmental’ attachments, are unsuitable for a range of reasons related primarily to horizontal and vertical cutting accuracy, spillage (residuals), water generation, and access.

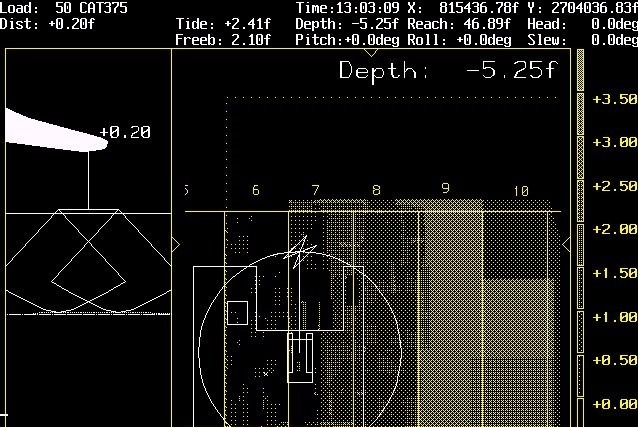

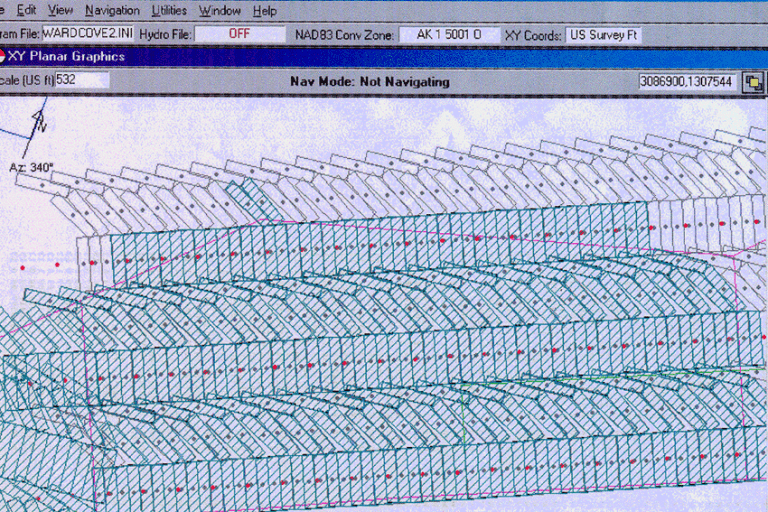

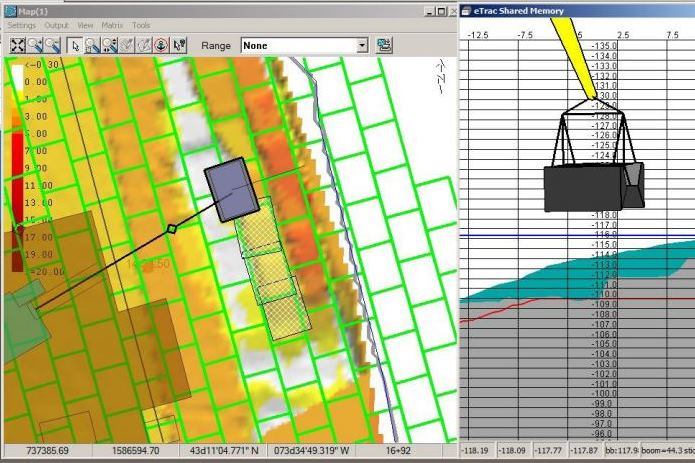

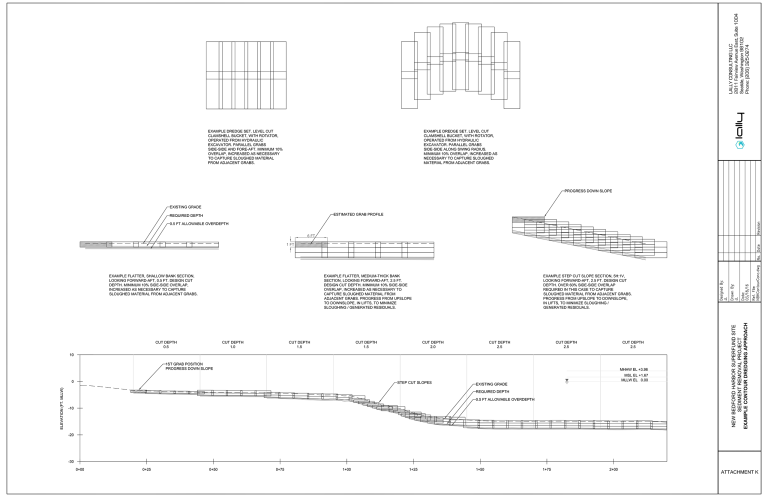

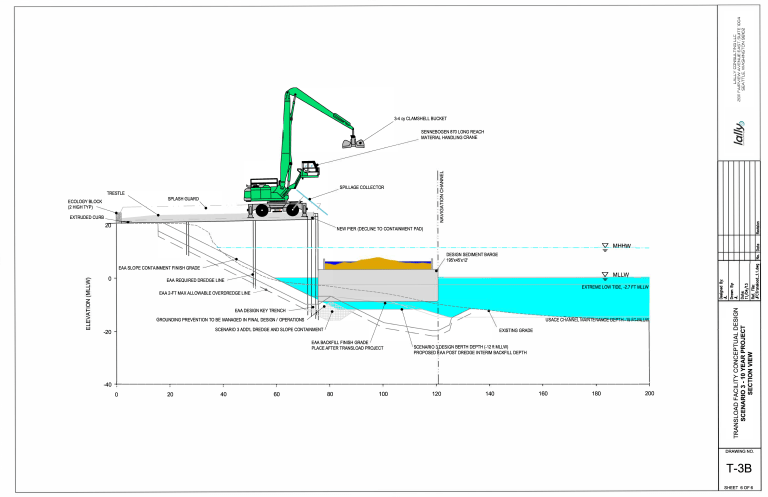

In the late 1990s-2001, as Dredging Technical Lead on several projects including New Bedford Harbor Superfund Site, Hudson River, and Boeing Plant 2 projects, Lally postulated, proposed to U.S. EPA Region 1 and USACE – New England District, designed and managed the first precision dredging project using RTK-GPS positioning and level-cut sealed environmental bucket in North America at the New Bedford Harbor Superfund Site. As specified by Lally and coordinated with leading U.S. and Dutch dredging contractors, this was also the first ever Shallow-draft Hybrid Mechanical – Hydraulic Transport Dredge assembled and demonstrated. In 2000-2001, as Site Design Engineer and Construction Manager, Lally oversaw engineering and construction implementation of the first precision thin-layer capping methods at the Ward Cove Superfund Site in Alaska.

A range of environmental dredging and capping approaches were developed on these two landmark projects;

- Precision Excavator Dredge with Rotator for Uniform, Parallel Overlap between Bucket Grabs

- Level-Cut Sealed Environmental Clamshell Bucket, to minimize overdredging and unnecessary transport and processing of clean native substrate beneath the contaminated inventory,

- RTK-GPS Electronic Positioning and Telemetry Systems for sub-centimeter level bucket placement accuracy,

- Precision Contour Dredge Prism Design,

- Water Reduction Strategies,

- Real-time Dredge Sediment Monitoring from Cab,

- Multi-phase (Progress) Post-Dredge Sampling,

- Spillage / Residuals Measurement and Management Techniques,

- Step Cuts and Slope Management,

- Multibeam Surveys for Improved Design and Implementation,

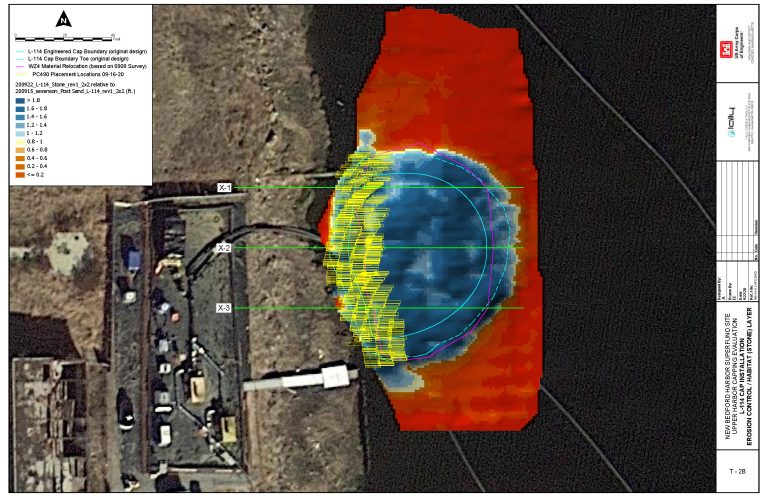

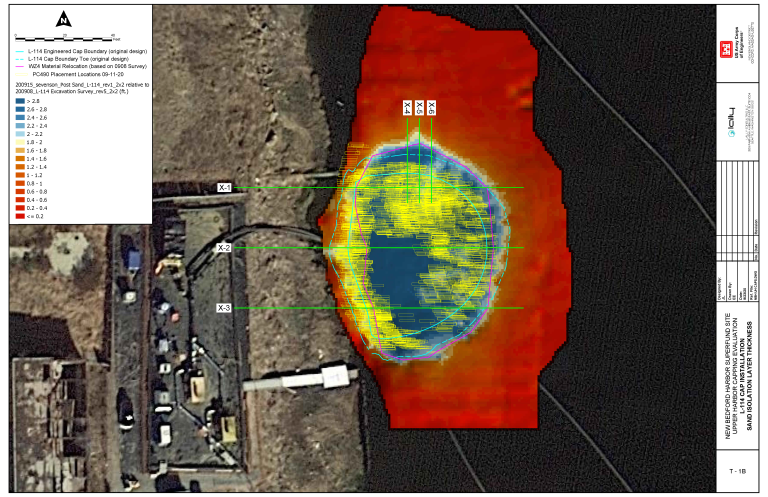

- Precision Cap Prism Design,

- Thin Layer Cap Placement by SWATH Approach

- Dredge and Cap Production Engineering

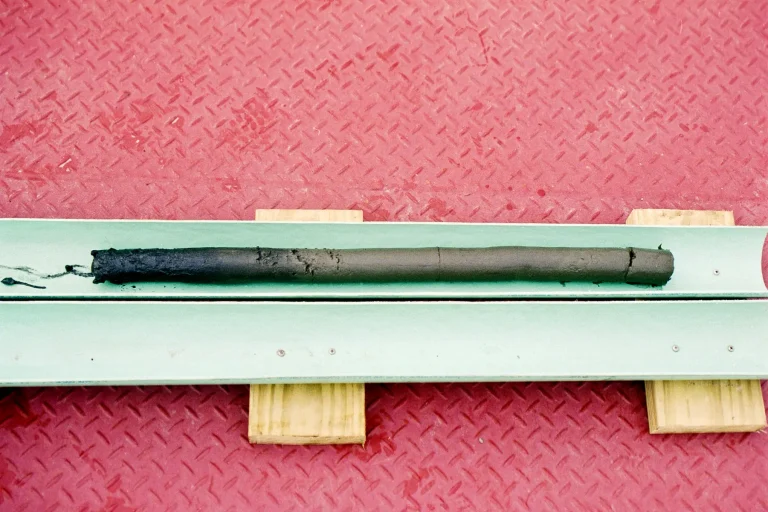

- Advanced Sediment Characterization Methods

- Advanced Performance Assessment Methods

To advance industry knowledge, beginning in 2001, Lally began educating the sediment remediation community of these environmental dredging and capping breakthroughs, with delivery of numerous presentations, teaching sessions and guidance documents. These engineering design and technology initiatives were broadly adopted, and since served as the basis for most contaminated sediment remediation projects in North America.

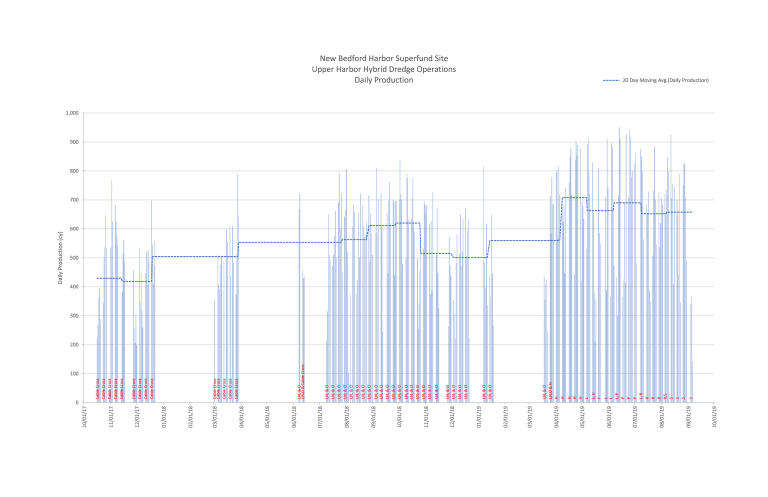

Lally LLC continues to lead development and implementation of precision dredging and capping platforms, next-generation dredge and bucket guidance systems, correlative precision dredge prisms, sampling campaigns, and situ and remote measurement and quality control systems. We regularly achieve overall dredging accuracies within 0.15 ft. of target elevation for our clients, as well as high production thin-layer capping, with greater and greater efficiency saving projects substantial capital in attaining site cleanup goals.

Partnering with our clients and oftentimes multi-disciplinary teams and federal and state regulators, Lally LLC plans complex sediment remediation projects with essential data, advanced modeling, engineering and construction know-how, to achieve cleanup goals with optimal performance, safety and cost savings.

Experience has shown that thorough and accurate site characterization studies are required in order to successfully complete sediment remediation projects. Lally LLC provides authoritative knowledge on the physical and environmental parameters important to achieve project success.

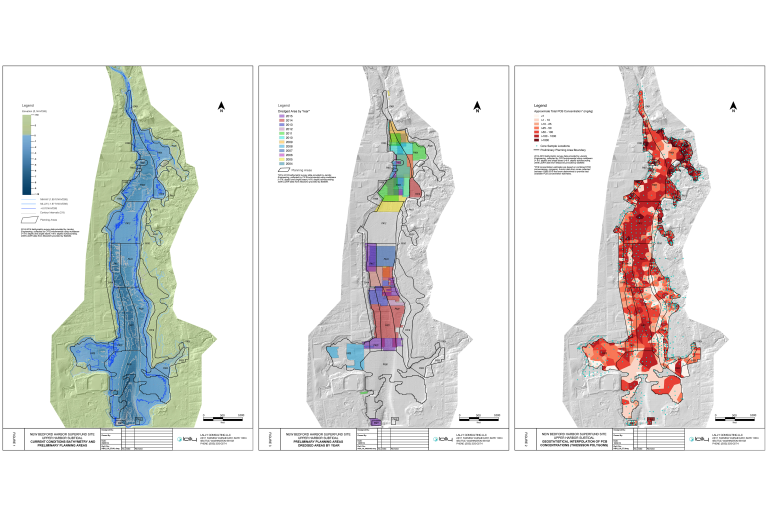

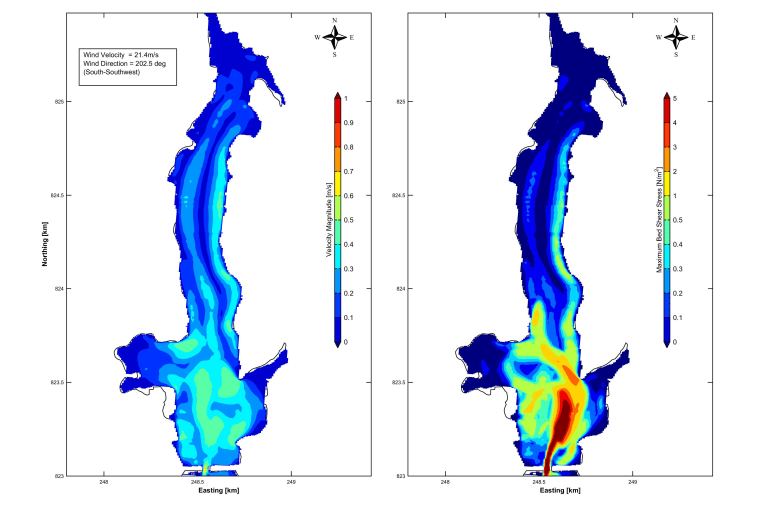

We offer a range of site data acquisition, analysis and mapping services to delineate contaminant inventory, characterize physical properties (i.e. geotechnical, debris), assess advection/diffusion processes related to contaminant transport and cap design, and bring overall clarity during the project formulation and pre-design phases to establish solid foundations for engineering design, contracting and construction implementation.

We offer the following contaminated sediment project planning services worldwide;

- Remedial Investigations / Feasibility Study

- Site Characterization Guidance

- Sampling and Analysis Plans

- Sediment Coring and Surface Sampling

- Geotechnical and Subsurface Investigations

- Debris Identification and Mapping

- Chemical Sampling and Analysis

- PFAS Assessment of Physical Characteristics

- Geostatistical Interpolation (e.g. Kriging)

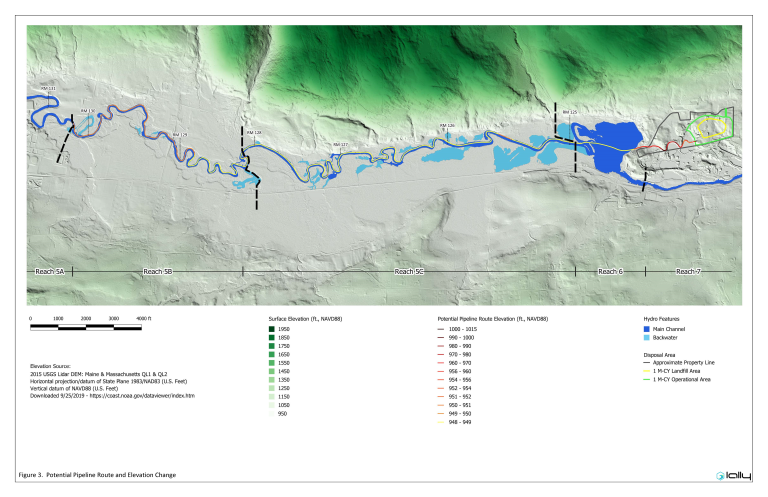

- LIDAR, Hydrographic and Marine Geophysical Surveys

- Mapping and Visualization Services

- Habitat Mapping

- Conceptual Site Models

- Setup of Confirmatory Sampling Program

- Establish Sample Spacing and Data Quality Objectives

- Pipeline Route Planning

- Sediment and Soil Treatment Planning

- Mechanical Dewatering Planning

- Volume and Mass Balance Estimates

- Production Estimates and Schedule Analysis

- Cost Estimates

- Early Contractor Involvement

- ENR and MNR Planning

- Dredged Material Disposal Planning

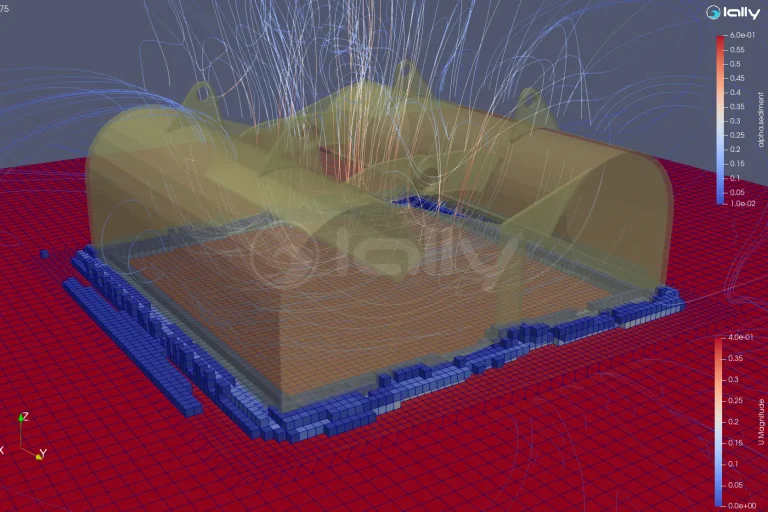

- FATE Modeling

- Beneficial Use Planning

- Building with Nature Planning

- Climate Change Adaptation

- 2D and 3D Visualizations

- Diver-Engineer Inspections

- MetOcean Data Collection and Statistics

- Data Analytics

- Training and Mentoring

Lally’s innovative and reliable remedial design approaches incorporate comprehensive understanding of geotechnical, chemical, hydrodynamic and sediment transport processes, environmental and other critical site conditions information, alongside industry-leading knowledge of environmental dredging, materials transport, processing and placement equipment and methods.

To minimize risk we develop Contract Plans and Specifications to be detailed, accurate, and without ambiguity. We establish appropriate conventional and specialized dredging, capping, enhanced natural recovery, and associated technologies, post-dredge sampling and SWAC calculations to achieve project cleanup goals as cost-effectively as reasonable.

As a pioneer in the development of precision contour dredge and capping equipment and correlative plans and prism files, we know how to temper optimal equipment types and sizes with appropriate resolution, offsets and tolerances considering site conditions. Lally has been teaching consulting engineers and contractors the fundamentals of precision dredging and capping approaches since the early 2000s and is often brought in to help setup prism designs and tune equipment to resolve residuals, cleanup efficiency, overdredging or production issues. We also have significant hydraulic dredging engineering experience to be able to design or specify appropriate hydraulic dredge types, cutterheads, pump and pipeline systems, and automation controls as conditions warrant.

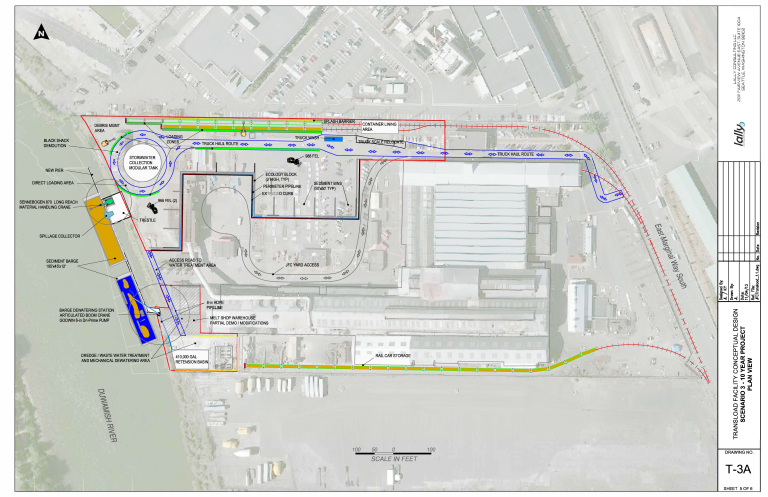

Further, Lally has deep experience in the design and operation of Shallow-Draft Precision Mechanical – Hydraulic Transport Hybrid Dredges, a system with several significant performance benefits at many larger contaminated sediment sites with restricted access.

Lally-offered Remedial Design and Engineering services include;

- Data Gap Analysis

- Topographic, Intertidal & Hydrographic Surveys

- Marine Geophysical and Subsurface Surveys

- Debris Surveys and Mapping

- GIS Data Management and Mapping

- Geostatistical Interpolation (i.e. Kriging, IDW)

- Sediment Sampling for Suitability Determinations

- Dredge Prism Design

- Engineered Cap Design

- Contaminant Flux Modeling (e.g. CAPSIM)

- Enhanced Natural Recovery Design

- Setup of Confirmatory Sampling Program

- Dredging Engineering

- Pipeline Route Planning

- Sediment and Soil Treatment Planning and Optimization

- Mechanical Dewatering Design

- Volume and Mass Balance Estimates

- Production Estimates and Schedule Analysis

- Carbon Amendment Delivery Design

- Dredged Material Disposal Planning and Management

- Nearshore Confined Disposal Facility Design

- Confined Aquatic Disposal (CAD) Cell Design

- FATE Modeling

- Hydrodynamic Modeling

- Climate Change Adaptation

- Slope Stability Analyses

- Beneficial Use Engineering

- Nature-based Engineering

- Contract Plans & Specifications

- Determination of Optimal Contracting Mechanisms

- Precision Excavator Dredge Design

- Hybrid Mechanical – Hydraulic Dredge Design

- Hydraulic Dredge Design

- Hydraulic Capping Barge Design

- Support Equipment Design

- Procurement Support

- Cost Estimates

- Dredge Contractor Selection

- Project Management

- Construction Oversight

- Construction Work Plans

- QA/QC Plans

- Environmental Monitoring Plans

- Quality of Life Monitoring Plans

- Training and Mentoring

These experience-based services have saved our sediment remediation clients hundreds of millions of USD dollars.

“Lally provided the project with innovative thinking, designs, and consistently educated the project team on the concepts and technical specifics of cleanup efficiency, dredge volume reduction, production optimization, and quality control that ensured project success. Overall these items and others resulted in a project cost savings on the order of $100M.”

– Superfund Mega-site Project Manager

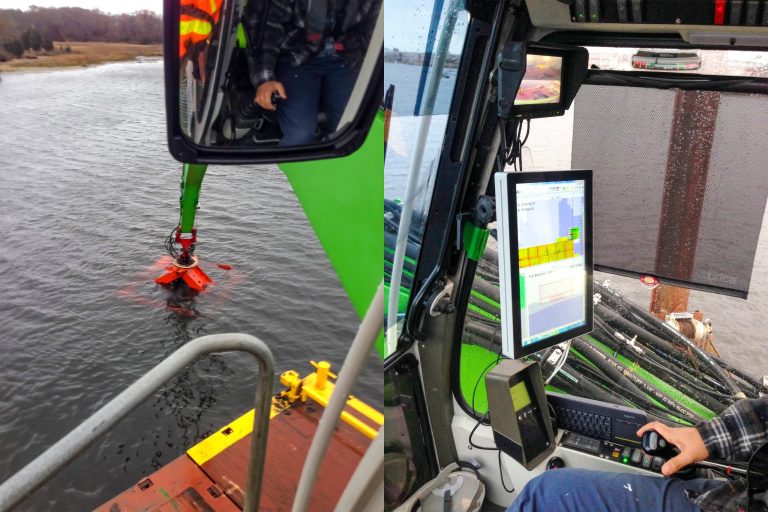

Remedial construction projects can be challenging, for a lot of reasons. With over 30 years’ experience as marine remediation contractor and consulting engineer, Lally understands the nuances and potential pitfalls on remediation construction projects, and excels in promoting performance, integrity, and safety.

In the lead-up to and during construction, Lally LLC can contribute as Project Manager, Owner’s / Contractor’s Representative, or 3rd Party Technical Advisor. Whether engaged from beginning to end, or at certain points, we identify varied ways to improve performance on contaminated sediments sites, and work collaboratively with project teams to optimize, and resolve project technical and contractual challenges.

Examples of construction-phase services recently completed by Lally LLC, mostly on Superfund Mega-sites, include;

- Project Management

- Training and Mentoring

- Construction Management

- 3rd Party Technical Oversight

- Sediment Remediation Expert Services

- Remediation Design and Construction Training

- Precision Dredge and Capping Equipment Design

- Dredge and Cap Barge Positioning

- Dredge Positioning and Automation

- Flow and Slurry Density Measurement

- Booster Pump Layout

- Dredge and Capping Prisms and Target Files

- Error Budgets

- Contractor Work Plan (RAWP) Development

- Residuals Management

- Setup of Confirmatory Sampling Program

- Sampling and Analysis Plans

- Establish Sample Spacing and Data Quality Objectives

- Real-time Sediment Monitoring

- SWAC Calculation Guidance

- Dredge and Capping Production Optimization

- Sediment Processing Optimization

- Water Management Optimization

- Activated Carbon Amendment Design

- Debris Mapping and Management

- CAD Cell Disposal Management

- FATE Modeling

- Engineered Cap Design

- Nature-based Engineering

- Underwater Confinement Berm Design

- Underwater Sill Design

- Site Engineering

- Sediment Sampling and Analysis

- GIS Data Management

- 2D and 3D Visualizations

- Diver-Engineer Inspections

- Pre-, Progress and Post-Dredge and Placement Surveys

- Dredging and Capping Performance Analyses

- Verification Plots and Data Analytics

- Acceptance Requests / Contract Management

- Quality Assurance / Quality Control

- Audits of all Quality-affecting Activities

- Environmental Monitoring

- Quality of Life Monitoring

- Public Meetings Support and Infographics

- USEPA Representation with Stakeholders

- Project Completion Reports and As-Builts

- Expert Litigation Support

Lally is glad to help you realize better performance, risk management and cost savings on your next sediment remediation site.

Practical Expertise

Slip 4 EAA Sediment Remediation Project Construction Oversight