Underwater Inspections

Value-added Diving and ROV Services to Accomplish a Range of Missions

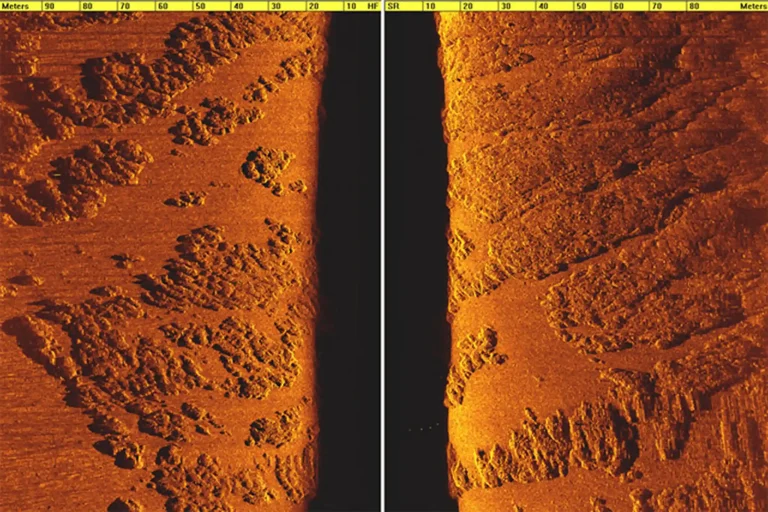

In addition to wide area coverage echosounder surveys and sonar imaging, Lally LLC can provide detailed inspections for a range of marine infrastructure, habitat assessment, and vessel management needs. We are also equipped to assist with marine archaeological and search & recovery missions.

As a standalone service, or part of larger infrastructure development and maintenance programs, Lally LLC offers a wide variety of specialized remote sensing technologies to accomplish various tasks.

From our offices in North America, Europe and the Caribbean, we can deploy, often rapidly, and operate the following equipment;

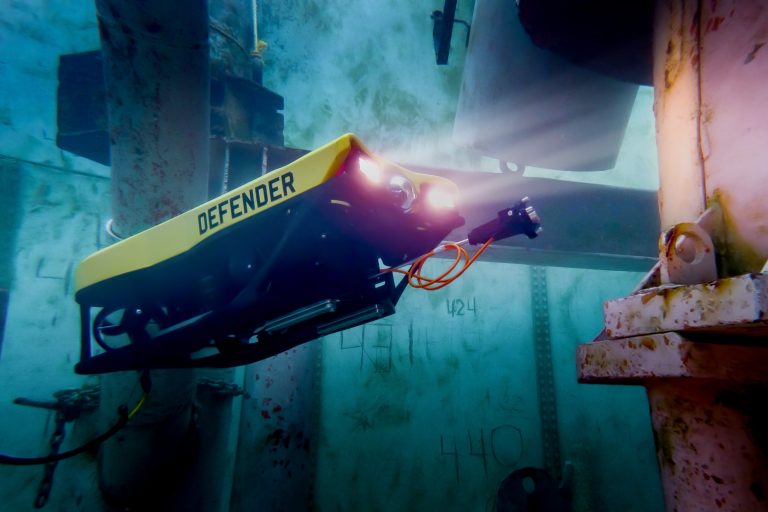

- Small and Mid-sized Underwater Remotely Operated Vehicles (ROV)

- SCUBA Inspection and Recovery (e.g. Lift bags) Equipment

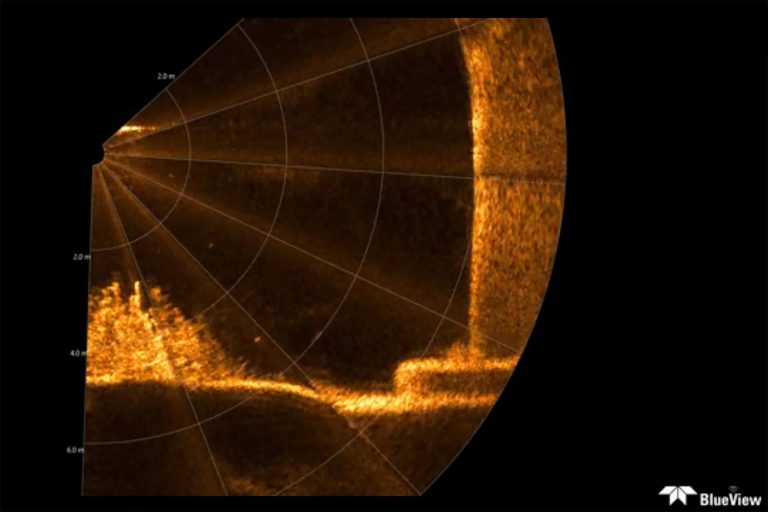

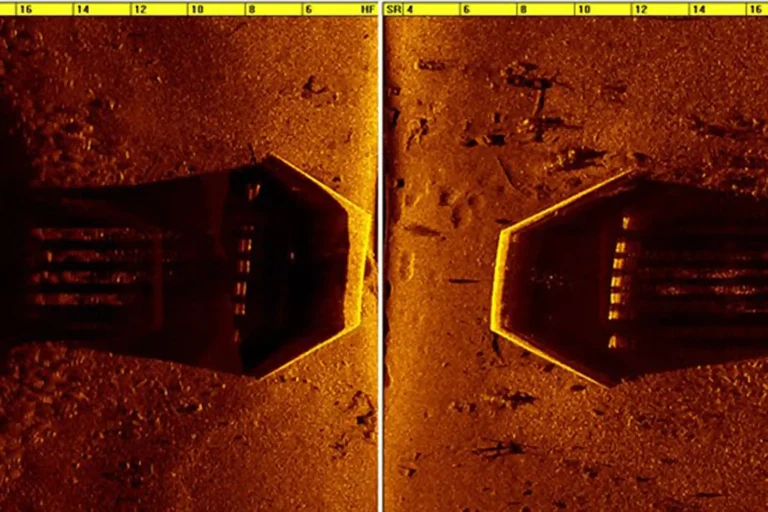

- 2D Imaging and 3D Multibeam Scanning Sonar

- Acoustic Doppler Current Profilers (ADCPs)

- Unmanned Surface Vehicles (USV)

- Unmanned Aerial Vehicles (UAV)

- Various Video Systems

- Pipeline Inspection Crawlers

- Manipulator Arms, Thickness Gauges, and Samplers

We complete inspections safely and efficiently, with a deliverable package including high definition video, photos and written report based on client requirements.

Lally LLC ROV Operators and Engineer-Divers can safely inspect marine infrastructure and facilities using a wide variety of specialized remote sensing technologies, in oftentimes hard-to-reach or challenging environmental conditions. The types of infrastructure inspections we offer include;

- Bridges

- Dams

- Erosion Control and Rock-Covered Pipeline (RCP)

- Piling, Sheet Pile and Cofferdam

- Offshore Outfall / Intake

- Mooring Chain

- Quay Wall

- Pipeline

- Water Tank

- Low Visibility

Where feasible, ROV inspections provide several benefits over commercial hard hat or SCUBA dive inspections, including;

- Dramatically reduces or eliminates field safety risks,

- Can provide higher quality video and data collection,

- More efficient and cost-effective.

In the case of potable water tank inspections, for example, we can maneuver the ROV to achieve a more thorough inspection and video record while avoiding the risks associated with confined entry, and without the need to drain the tank. For underwater inspections in alligator- and shark-infested waters the safety advantages of ROV are also obvious.

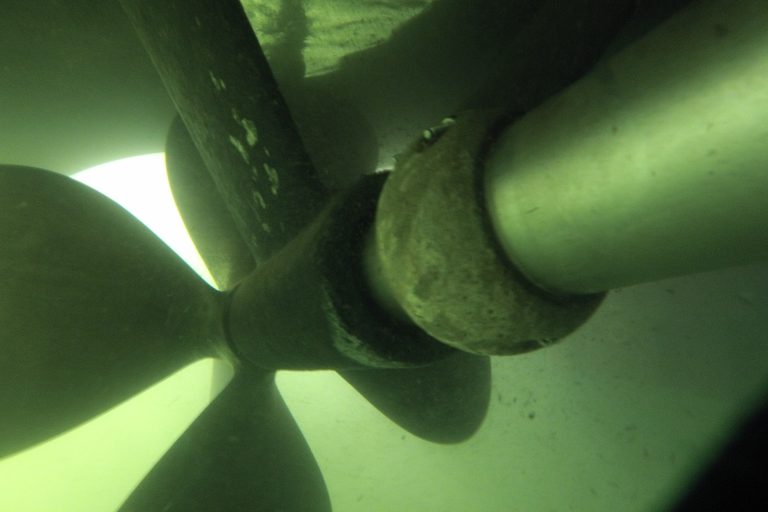

Lally ROV Operators and Engineers perform underwater inspections of vessels and offshore platforms using a variety of equipment based on the assignment.

We offer ROV inspections services to the following sectors;

- Defense

- Port Security

- Border Security

- Offshore Oil & Gas

- Commercial Shipping

- Offshore Renewable Energy

- Dredging and Marine Construction

- Motor and Sailing Yacht

- Recreational Vessels

- Fishing Industry

- Marine Salvage

- Aquaculture

for such considerations;

- Damage Assessment

- Hull Thickness Measurement

- Propulsion Inspection, Mains and Thrusters

- Monopile, Jacket and Scour Protection Inspections

- Offshore Rig Inspection, Maintenance and Repair (IMR)

- Cathodic Protection

- Biofouling

- Moorings

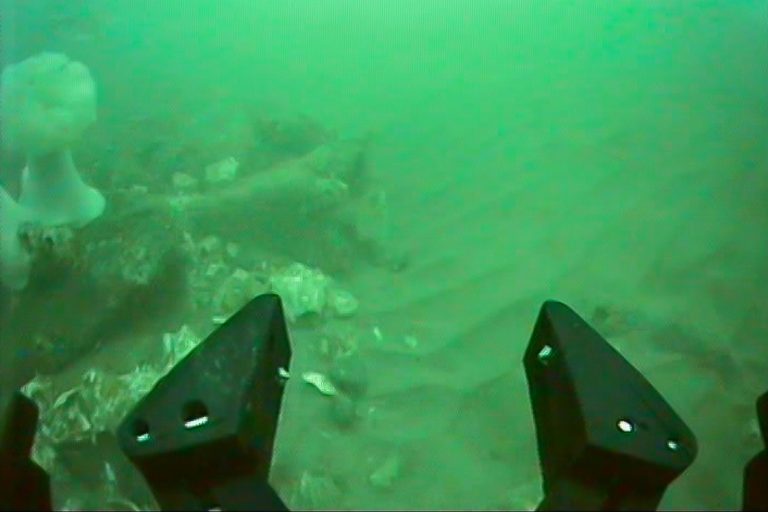

Lally LLC Scientist-Divers, Engineer-Divers and ROV Operators perform offshore/nearshore reef and seagrass surveys, assess habitat quality, and collect seabed substrate samples. We employ SCUBA, specialized in situ sampling devices, and lift bag technologies when needed for such tasks as oceanographic equipment deployments (i.e. acoustic doppler current profilers) and sample recoveries.

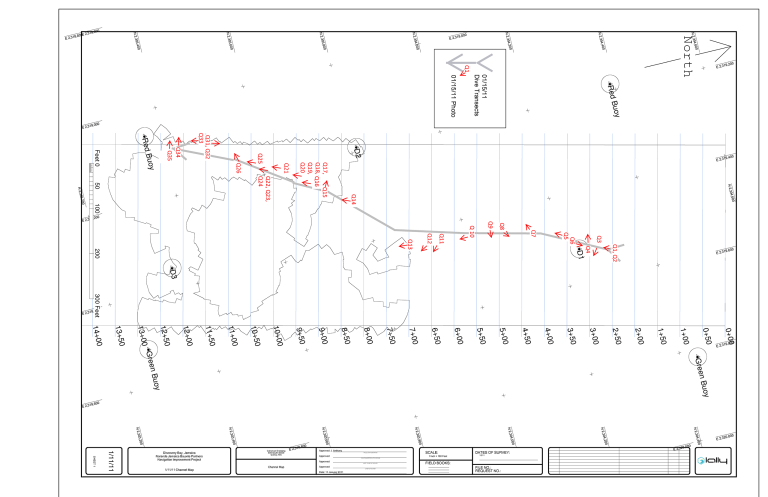

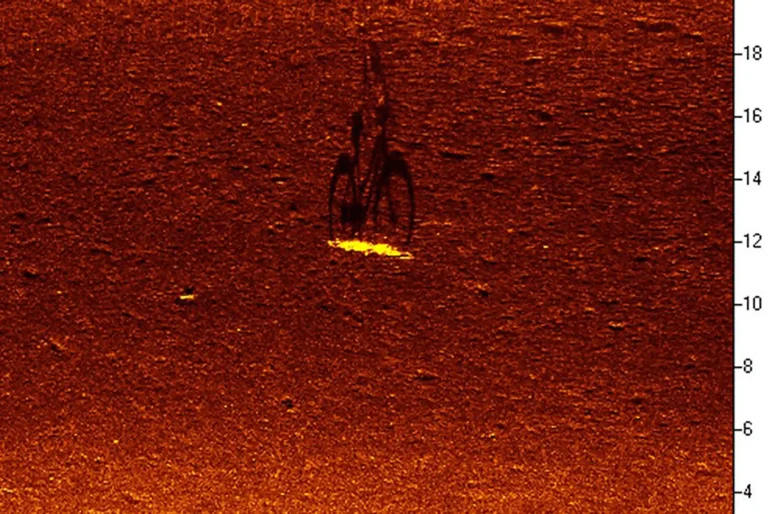

Deploying ROVs we can assist universities and government agencies in conducting seagrass, coral reef and other marine mapping surveys over larger areas. Our underwater research also extends to exploring marine archaeological and wreck sites.

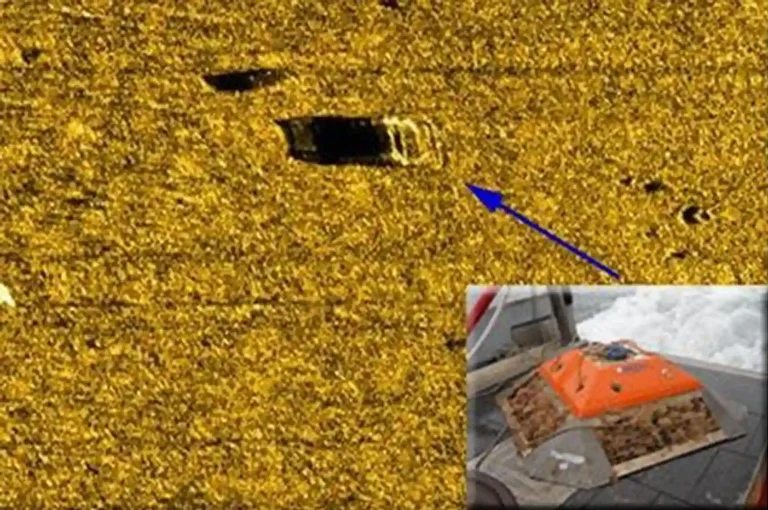

Lally LLC is equipped with multiple technologies to assist government agencies, police, commercial or private parties in conducting search & recovery operations of various types in inland to nearshore waterbodies.

Safety is a core value at Lally LLC. We have completed tens of thousands of hours of field work in the marine environment offshore, on floating plant, oftentimes in harsh conditions, and have never had a health or safety incident of any kind. Through care and diligence, we aim to maintain this zero-incident record.