Dredged Material Management

Smarter than Dirt

It’s surprising to many the importance, complexity and costs involved with Dredged Material Management. Whether for large-scale capital works, channel maintenance, beach restoration or contaminated sediment programs, there are always substantial sums to be saved and benefits won in optimizing the way the seabed is dredged, and dredged materials are transported, beneficially used or disposed of.

Lally LLC engineers are experts in the field of Dredged Material Management and know how to achieve optimal results through smart planning and technical approaches. On all large projects, we strive to understand sediment conditions as they lie on the seabed, during transport, and ultimate disposition. Oftentimes this involves extensive bench-scale testing, and engagement with sediment processing specialists. With over three decades of experience, much of it working with leading multi-national marine remediation contractors, Lally LLC is particularly adept in innovative dredging and dredged material transport technologies and methods, passive and mechanical sediment dewatering, beneficial use of sediments, and Nature-based solutions.

Lally LLC engineers and scientists provide Dredged Material Management experience and services globally from our offices in North America, Europe and the Caribbean, including;

- Project Planning

- Field Investigations and Data Collection

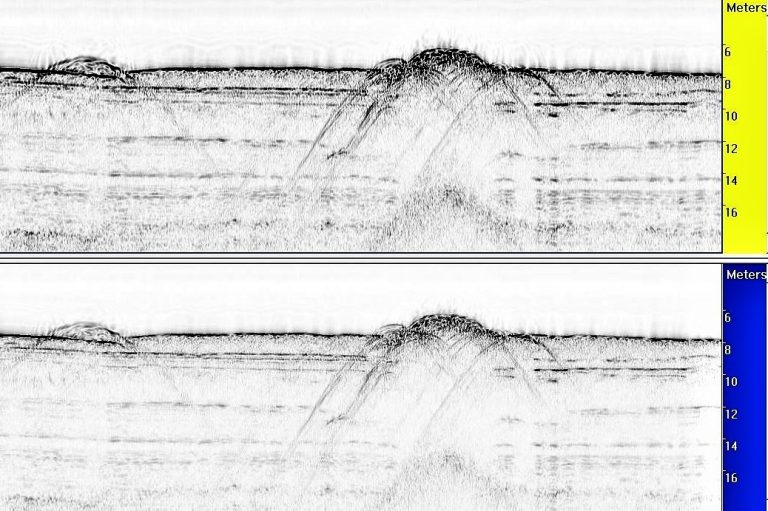

- Geotechnical and Subsurface Investigations

- Sediment Sampling for Suitability Determinations

- Dredge Elutriate, Leachate and Turbidity Testing

- Open Disposal FATE Modeling

- Beneficial Use Evaluations

- Sediment Processing

- Soil Conditioning

- Clean PFAS-containing Soil

- Mechanical and Passive Dewatering

- Nature-based Solutions

- Sediment Compatibility Analysis

- Erodibility Analysis

- Bulking Estimates

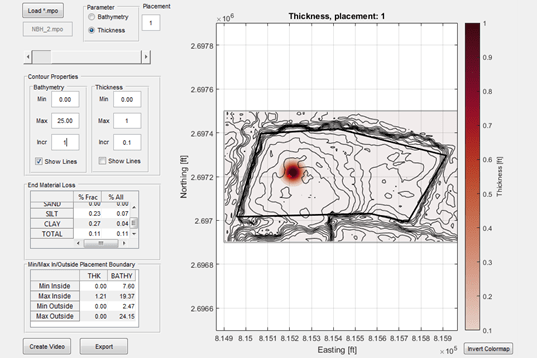

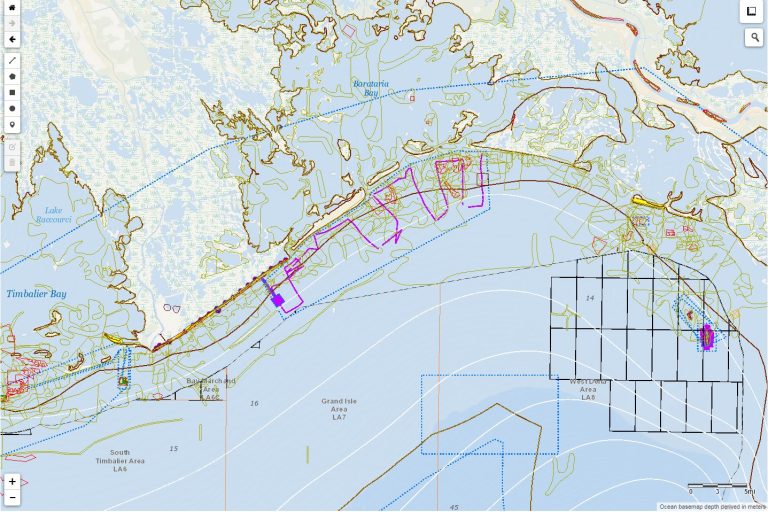

- Sediment Transport Modeling

- Water Quality Predictions, Monitoring and Management

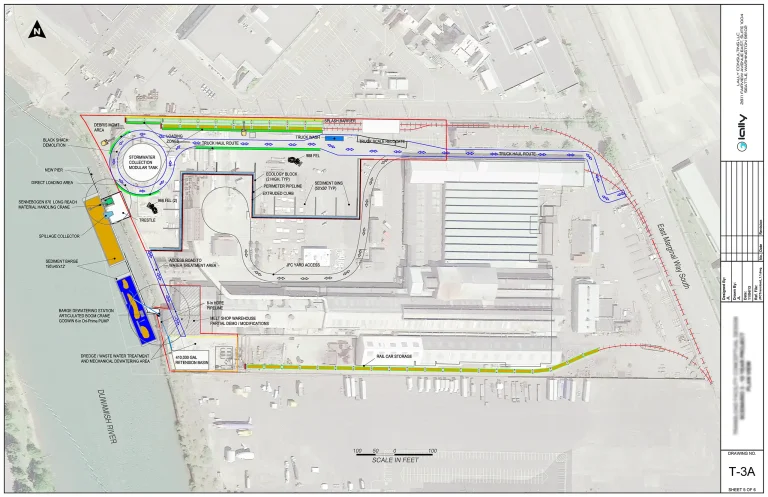

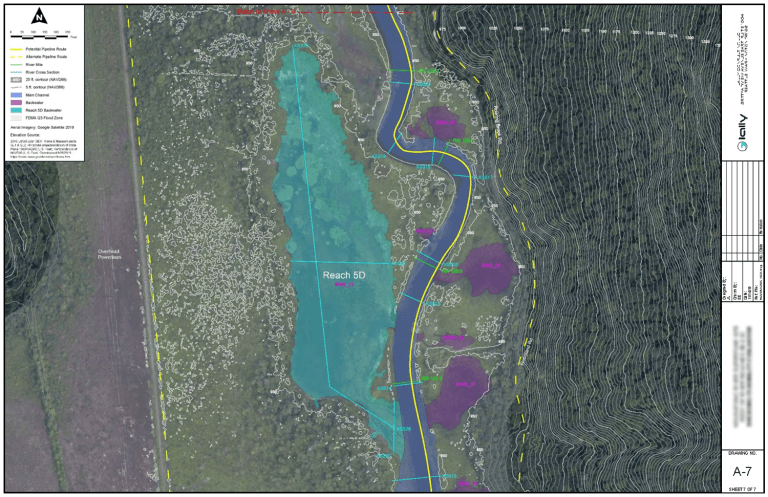

- Transload Facility Planning and Design

- Transport and Placement Methods and Planning

- Railroad and Truck Planning and Logistics Planning

- Production Estimates

- Cost Estimates

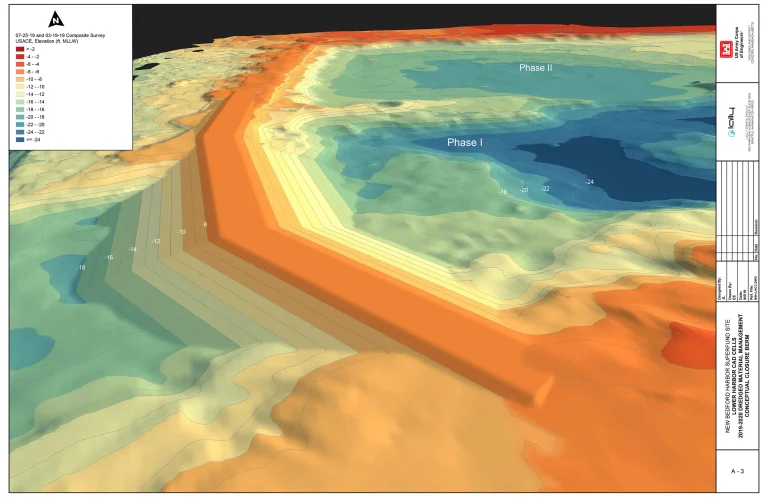

- Confined and Unconfined Disposal Area Design

- Reclamation (Fill) Area Design

- Sedimentation Basin Design

- Beach and Wetland Design

- Contract Plans & Specifications

- Determination of Optimal Contracting Mechanisms

- Upland Confined Disposal Facility (CDF) Design and Management

- Confined Aquatic Disposal (CAD) Cell Design and Management

- Nearshore Surf Zone Placement Design

- Beach Fill Management

- Wetland Fill Design and Vegetative Plantings

- Project Management

- Procurement Support

- Construction Management

- Regulatory Permitting

- Environmental Monitoring

- Sediment Monitoring

- Stakeholder Engagement

- Public Meeting Presentations

Whether to assess grain size compatibility for beach and wetland restoration, suitability determinations for offshore open-water disposal, or chemical analytical testing to determine processing and confinement requirements for contaminated sediment, Characterization Studies are vital to the success of dredging projects.

Lally LLC engineers have decades of experience in the field collecting sediment samples, conducting geotechnical and bench-scale testing in the laboratory, and building and executing Sampling and Analysis Plans for contaminated sediment sites.

We offer the following Sediment Characterization services worldwide;

- Site Reconnaissance

- Sampling and Analysis Plans

- Sampling Equipment Selection and Design

- Sediment Coring and Surface Sampling

- Subsurface Investigations

- Debris Identification and Mapping

- Geotechnical Sampling and Analysis

- Dredge Elutriate, Leachate and Turbidity Testing

- Chemical Sampling and Analysis

- Geostatistical Interpolation (e.g. Kriging, Thiessen Polygons)

- Open Water FATE Modeling

- Erodibility Modeling

- Plume Modeling

- Borrow Source – Shoreline Sand Compatibility Analysis

- Hardbottom and Seagrass Mapping

- Data Analytics

- 2D and 3D Visualizations

- Conceptual Site Models

Dredged material disposal can represent a large project cost, oftentimes on the same order or higher than the cost of dredging operations themselves. But it can also represent opportunity. In our experience, all clean dredged materials, including rock, gravel, sand, silts and clays have resource value and can be used creatively and beneficially.

Such opportunities include habitat creation/enhancement, shoreline erosion control, flood management, and construction fill, oftentimes within short, economical distance of the dredging location. Even contaminated sediment, which can cost in excess of $800 USD per ton for transport and disposal at regulated upland facilities (landfills), may be processed to yield a significant clean sand fraction for beneficial use as construction fill, and greatly reduce the overall disposal cost burden on many projects.

Since the early 1990’s Lally has been involved with the planning, engineering and construction of Beneficial Use of Dredged Material (BUDM) projects, foremost in North America, but also fostering the application of technologies and methods developed in Europe abroad.

Our BUDM experience includes projects involving;

- Wetland Repair (silts and sands)

- Beach Restoration and Nourishment (sand)

- Nearshore Feeder Berms, (sand and gravel)

- Dike (Bund) Construction, (clay and rock)

- Habitat Islands (rock, silt and sand)

- Shoreline Armoring (rock)

- Screening and Washing of Sand, Course and Fines fraction from Contaminated Sediment for use in Construction Fill

Connect with us to help identify and implement cost saving Beneficial Use of Dredged Material opportunities on your project.

As former employees of North American and European dredge contractors, and with leading-edge academic knowledge, Lally LLC engineers have technical and operational expertise with hydraulic and mechanical dredges and a range of dredged material management processes.

Over the past decade Lally LLC has guided and assisted clients including the U.S. Army Corps of Engineers, U.S. Environmental Protection Agency, international dredging and marine contractors, ports, municipalities, industrial firms, and engineering and environmental consultants on a variety of dredge projects.

To develop optimal solutions for our clients, we work to understand sediment conditions as they lie on the seabed, and perform detailed dredging, processing and disposal alternatives evaluations. We offer our clients specialist knowledge of innovative dredging and dredged material transport technologies and methods, sediment processing, passive and mechanical dewatering, beneficial use of sediments, and nature-based technical approaches.

Lally LLC personnel have significant experience working with American and European sediment processing contractors and leading-edge technologies, assisting in establishing their applications on major contaminated sediment remediation sites in USEPA Regions 1, 2, 5 and 10.

Specific Sediment Processing experience Lally LLC offers includes;

- Site Reconnaissance and Team Building

- Sediment Sampling and Testing Campaigns (Geotechnical and Chemical)

- Bench-scale Dewatering Studies

- Design Setup and Management of Mechanical, Hydraulic and Hybrid Dredging Equipment

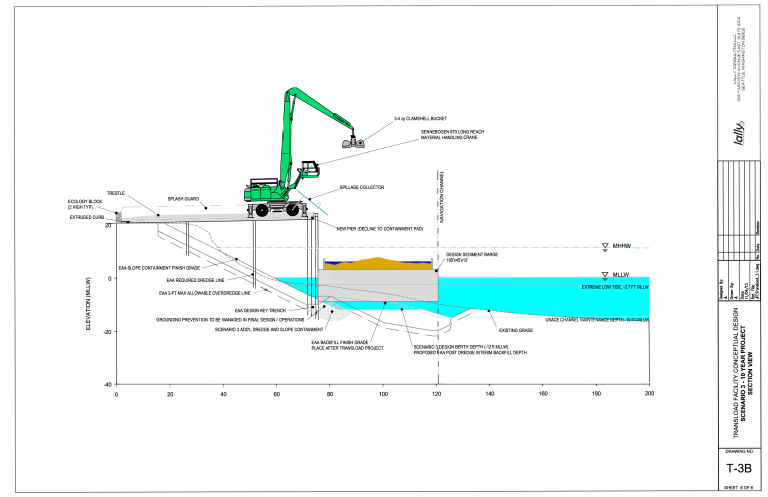

- Design of Sediment Transloading Facilities

- UXO screening

- Water Minimization Strategies (Hydraulic and Mechanical)

- Barge Decanting Methods

- Slurry Density and Pressure Monitoring

- Slurry Conditioning and Flow Control

- Automated Flocculant Dosing

- Mass Balance Calculations

- Course Fraction Separation (i.e. Rotating Sieve Drum, Shaker Screen)

- Sand Separation (i.e. Hydrocyclones)

- Pre-Thickener / Clarifiers

- Mechanical Dewatering (i.e. Belt Filter Press, Plate & Frame Press)

- Process Water Treatment

- Passive Dewatering (i.e. Amendments, Geo-textile Tubes)

- Disposal Alternatives Evaluations and Negotiations

- Beneficial Reuse of Clean Fraction

Dredged Material Management performance during construction often amounts to balancing many operational parameters and process steps. Lally LLC has technical and operational experience with conventional and specialized dredge and sediment processing technologies, large-scale dredged material transport, placement, and water management techniques, and the means to monitor and achieve best performance.

In the leadup to and during construction, we can effectively contribute as Project Manager, Owner’s/Contractor’s Representative, or 3rd Party Advisor to monitor and resolve technical and contractual challenges, improve overall system performance and achieve optimal disposition of project dredged materials.

Lally LLC offers the following services to assist project owners and contractor’s setup and execute dredged materials management projects successfully;

- Procurement Support

- Stakeholder Engagement

- Pre-Tender Meetings

- Equipment Selection

- Equipment Design

- Site Staging

- Project Mobilization and Startup

- Construction Oversight

- Environmental Monitoring

- Quality Assurance / Quality Control

- Dredge Optimization

- 24/7 Worldwide Support

- Process Water Management

- Barge Management

- FATE and Sediment Transport Modeling

- Discharge Placement (i.e. Diffusor) Design

- Predicting Deposition Footprint

- Predicting Return Water Quality

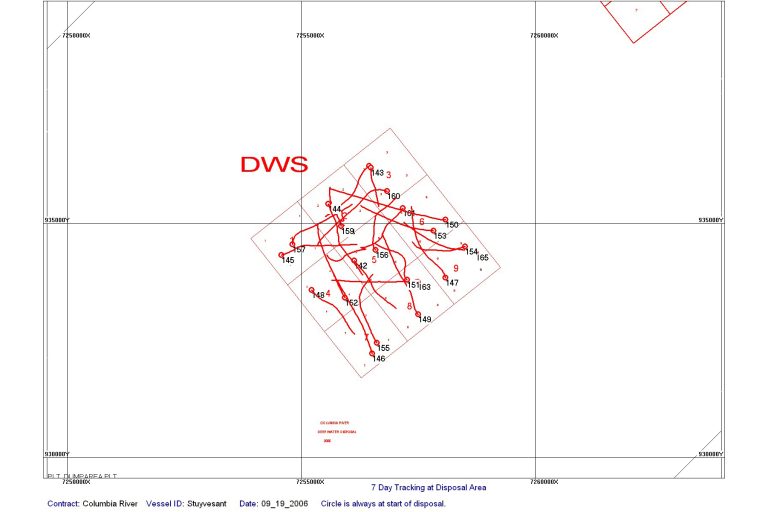

- Dredge and Disposal Positioning

- TSHD and Scow Barge Bottom Dump Optimization

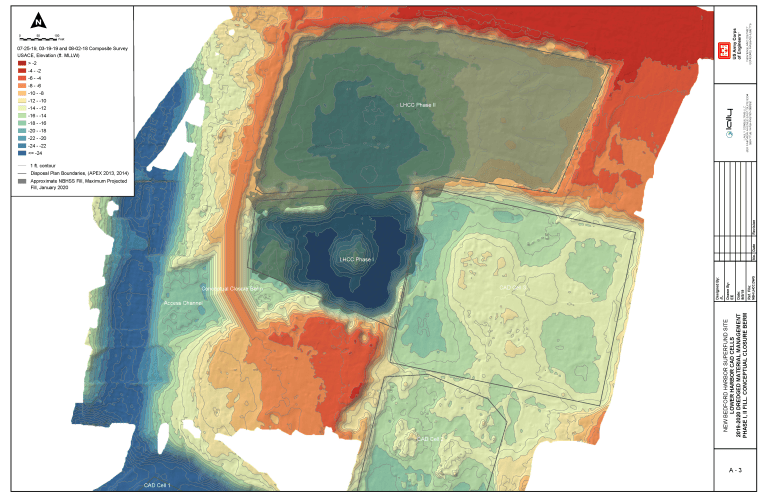

- Nearshore and Upland CDF Management

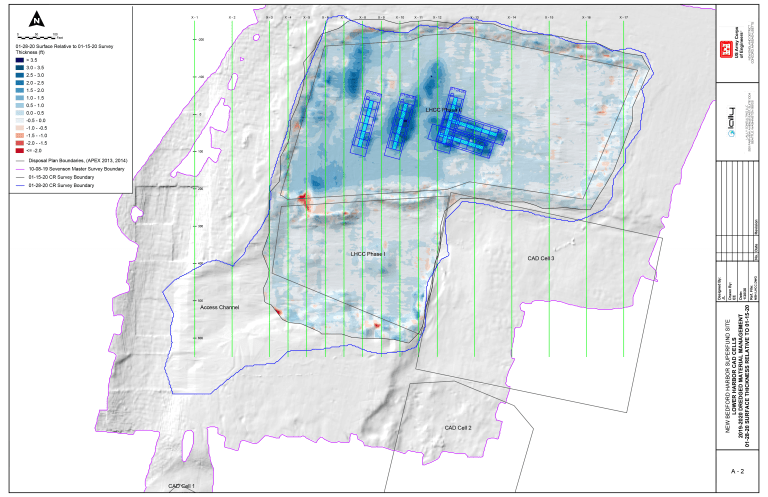

- Subaqueous CAD Cell Management

- Beach and Barrier Island Nourishment

- Offshore Open Water Bottom Dumping

- Nearshore Feeder Berms and Beaches

- Land Reclamation

- Weir Design and Management

- Plume and Water Quality Monitoring

- Pre-, Progress and Post-Placement Surveys

- Payment Requests / Contract Management

- Claims Resolution / Expert Witness Services