Environmental Dredging and Capping

Leading the Way with Accuracy, Production and Sediment Cleanup Efficiency

Environmental dredging projects fall into two primary categories; dredging contaminated sediments to achieve a clean seabed and dredging in contaminated sediment to achieve a required depth without the need to leave a clean seabed. In both cases and depending on several variables, specialized dredging technologies, methods and engineering standards are typically required. Lally is a pioneer and trusted authority in these areas.

As marine remediation contractor and consulting engineer, John Lally P.E. (Lally) has been fortunate to maintain a unique position at the forefront of environmental dredging planning, engineering and technology developments for over 30 years. Lally has worked on over 1,000 dredging projects involving hydraulic and mechanical dredge types, from small to some of the largest ever completed, and served in leadership roles on numerous environmental dredging and capping projects. Invaluable experience has been gained in the process, which we often share with clients, project partners and consultants in our ongoing pursuit of restored waterways and clean marine environments.

Lally LLC provides remediation site owners, managers, regulators, contractors, consultants, and other stakeholders a wide range of Environmental Dredging and Capping services, including;

- Project Management

- Remedial Investigations

- Feasibility Studies

- Geotechnical and Subsurface Investigations

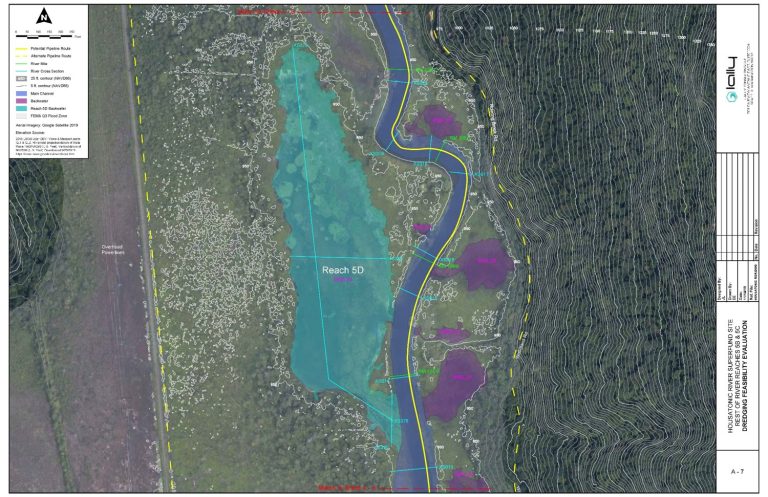

- Hydrographic and Marine Geophysical Surveys

- Mapping and Visualization Services

- Sediment Remedial Engineering

- Volume and Mass Balance Estimates

- Production Estimates and Schedule Analysis

- Dredging, Capping, Sediment Processing Equipment Analysis

- Precision Excavator Dredge Design

- Hybrid Mechanical – Hydraulic Dredge Design

- Hydraulic Capping Barge Design

- Enhanced Natural Recovery

- Carbon Amendment

- Procurement Support

- Plans and Specifications

- Cost Estimates

- Project Startup

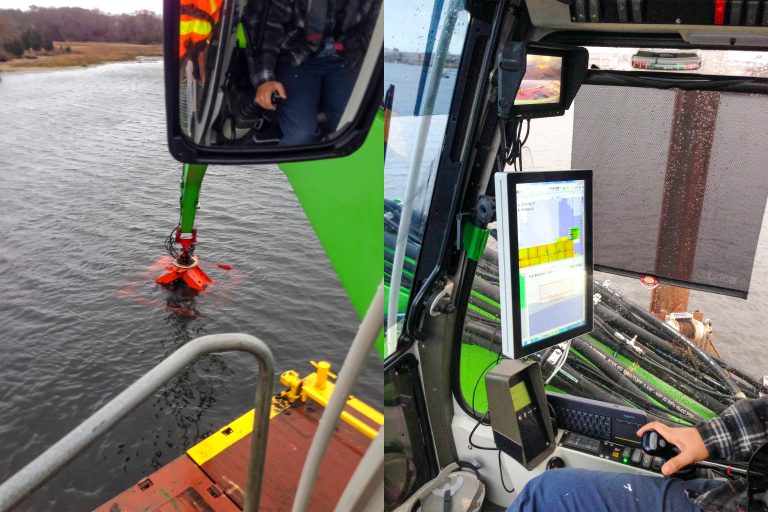

- Precision Dredge Setup

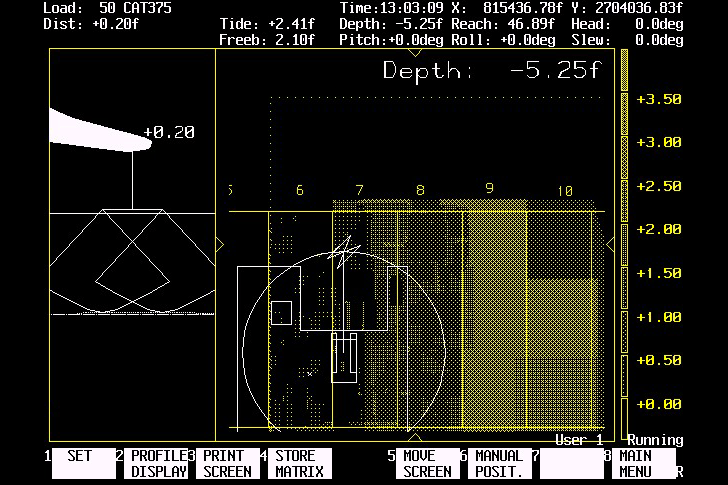

- Dredge Positioning and Automation

- Construction Oversight

- Performance Optimization

- Residuals Management

- Environmental Monitoring

- 24/7 Worldwide Support

The processing and disposal of contaminated sediment is expensive, often costing in excess of $800/ton. On larger sediment remediation sites, overdredging of clean native substrate beneath the contaminated inventory can lead to tens of millions of dollars unnecessarily spent by the project owner.

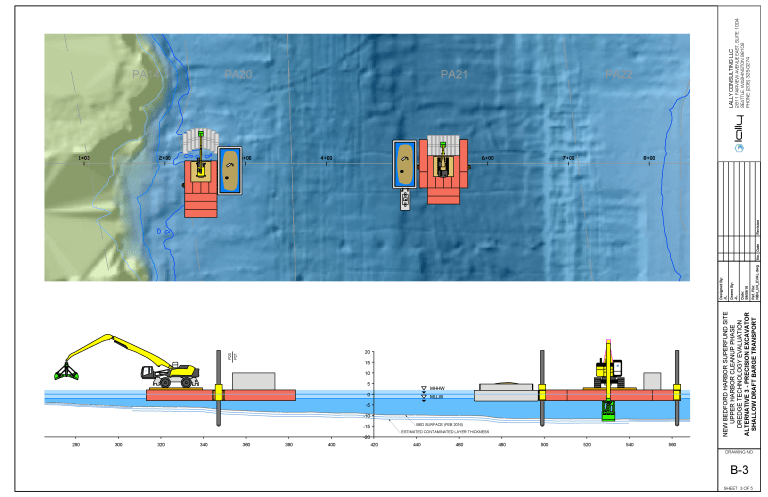

To help solve the problems of overdredging, production and cleanup efficiency, as dredging technical lead on several large sediment remediation sites in USEPA Regions 1, 2 and 10, Lally postulated, designed, and in 2000, managed the first precision dredging project using RTK-GPS positioning and level-cut sealed environmental bucket in North America at the New Bedford Harbor Superfund Site. Later that year, as site design engineer and construction manager, Lally led the first precision thin-layer capping project at the Ward Cove Superfund Site in Alaska.

A range of environmental dredging and capping approaches emerged from these two early projects that would help complex contaminated sites achieve cleanup with greater efficiency and cost savings, namely;

- Precision Excavator Dredge with Rotator for Uniform, Parallel Overlap between Bucket Grabs

- Level-Cut Sealed Environmental Clamshell Bucket, to minimize overdredging and unnecessary transport and processing of clean native material from beneath the contaminated inventory,

- RTK-GPS Electronic Positioning and Telemetry Systems for centimeter- level bucket placement accuracy,

- Precision Contour Dredge Prism Design,

- Hydraulic and Mechanical Water Reduction Strategies,

- Real-time Dredge Sediment Monitoring from Cab,

- Multi-phase (Progress) Post-Dredge Sampling,

- Residuals Measurement and Management Techniques,

- Step Cuts and Slope Management,

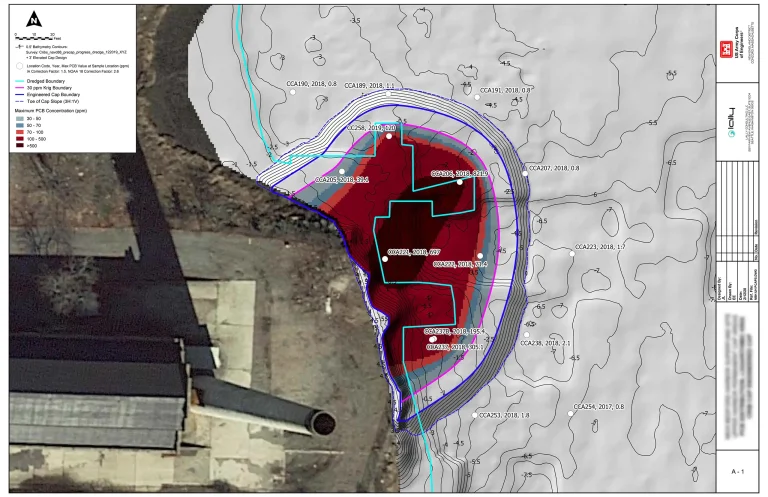

- Multibeam Surveys for Improved Remedial Designs and Construction

- Precision Cap Prism Design

- Thin Layer Placement with Capping SWATH Approach

- Dredge and Cap Production Engineering

- Advanced Sediment Characterization Methods

Beginning in 2001, Lally began educating the sediment remediation community on the range of engineering design and technology advances developed at these two early projects. These advances have since been broadly adopted and benefited numerous contaminated sediment remediation projects, including;

- New Bedford Harbor Superfund Site

- Hudson River Superfund Site

- Passaic River Superfund Site

- Portland Harbor Superfund Site

- Commencement Bay / Nearshore Tideflats Superfund Site

- Lower Duwamish Waterway Superfund Site

- Marathon, Peninsula Harbour Cleanup

- Gowanus Canal Superfund Site

- Newtown Creek Superfund Site

- Onondaga Lake Superfund Site

- Berry’s Creek Study Area Ventron/Velsicol Superfund Site

- … and many other sites.

Lally continues to lead development and implementation of precision dredging and capping platforms, next-generation dredge and bucket guidance systems, correlative dredge prisms, sampling and characterization campaigns, performance verification, and quality control systems. We regularly achieve overall dredging accuracies within 0.15 ft. of target elevation for our clients, while saving substantial capital in attaining cleanup standards. Based on broad project experience in varying seabed conditions, we have developed key residuals minimization methods, authored key guidance on these topics, and continue to innovate.

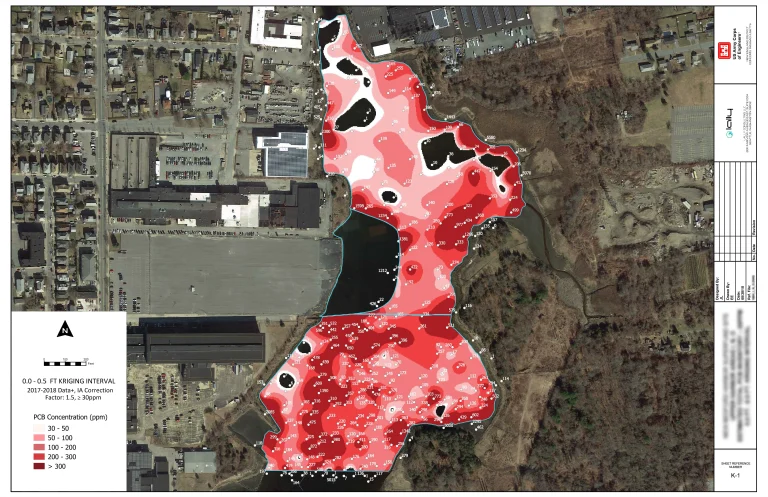

Experience informs us that thorough and accurate site characterization studies are required in order to successfully accomplish Environmental Dredging and Capping projects. We often see poorer performing projects to be those that have not acquired and analyzed site conditions data adequately.

Lally LLC provides expertise on the physical, chemical and environmental parameters important to achieve sediment remediation project success. We offer a range of site data acquisition, analysis and mapping services to delineate contaminant inventory, characterize physical properties, assess advection/diffusion processes related to contaminant transport and cap design, and overall bring requisite clarity during the project formulation and engineering phases.

We offer the following Data Acquisition, Analysis and Mapping services worldwide;

- Site Characterization Planning

- Sampling and Analysis Plans

- Sediment Coring and Surface Sampling

- Subsurface Investigations

- Debris Identification and Mapping

- Geotechnical Sampling and Analysis

- Chemical Sampling and Analysis

- Geostatistical Interpolation (e.g. Kriging, Thiessen Polygons)

- Topographic & Bathymetric Surveys

- Data Analytics

- 2D and 3D Visualizations

- Conceptual Site Models

From Formulation through Final Design, Lally LLC engineers Environmental Dredging and Capping projects with essential data, advanced modeling, and contractor know-how, to achieve cleanup goals with optimal performance, safety and cost savings.

Our dredge and capping project engineering approaches seek to incorporate comprehensive understanding of hydrodynamic and sediment transport processes, geotechnical, chemistry, sub-bottom, environmental and other important site conditions, alongside practical expertise with dredging, materials transport, processing and placement equipment and approaches.

Lally LLC Plans and Specifications are built to be detailed, accurate, and without ambiguities. We are pioneers in the development of several types of precision contour dredge and capping plans, with appropriate resolution, offsets and tolerances considering all site conditions and advanced equipment capabilities.

Lally has taught numerous project engineers, environmental consultants and other practitioners the fundamentals of precision dredging and capping and is available to help tune equipment and prism designs to optimally resolve overdredging residuals, and production or issues. Our experience-based services have saved hundreds of millions of dollars across North America sediment remediation projects and beyond.

Project Design and Engineering Services Lally LLC offers include;

- Project Planning

- Field Investigations and Data Collection

- Topographic, Intertidal & Hydrographic Surveys

- Marine Geophysical and Subsurface Surveys

- Geotechnical Investigations

- Dredge Prism Design

- Engineered Cap Design

- Quantity Calculations

- Computer Assisted Design (CAD)

- Geographic Information Systems (GIS) Data Management and Mapping

- Sediment Sampling for Suitability Determinations

- Sediment Processing and Beneficial Use

- Equipment and Technique Innovations

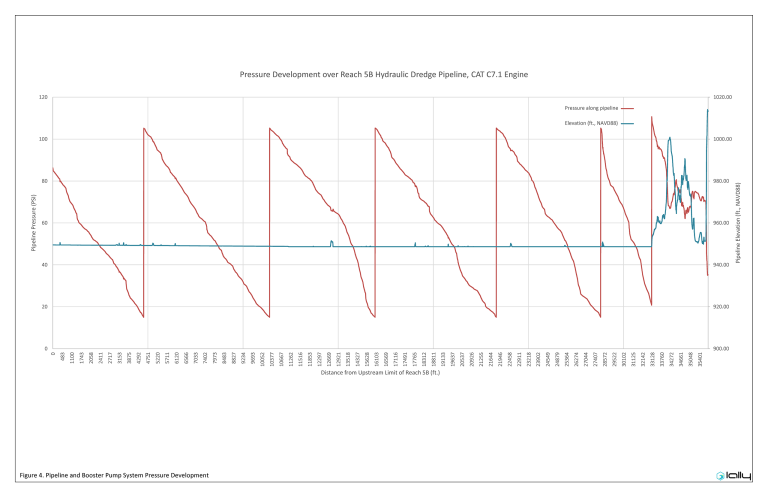

- Pipeline Routes

- Pump and Pipeline Calculations

- Production Estimates

- Cost Estimates

- Project Scheduling

- Contract Plans & Specifications

- Determination of Optimal Contracting Mechanisms

- Dredge Equipment Selection

- Dredge Contractor Selection

- Project Management

- Remediation Design and Construction Training

- Environmental Impact Studies / Biological Evaluations

- Construction Management

- Regulatory Permitting

- Permit Compliance / Environmental Monitoring

- Stakeholder Engagement / Public Meeting Presentations

- Claims Management and Negotiations

- Dispute Resolution / Expert Litigation Services

Incorporation of curvilinear planforms in engineered cap design is another Lally innovation augmented by the precision excavator placement method. The benefits of Curvilinear Caps TM are a significant new development in the remedial design toolbox, which if designed properly provide benefits including;

- Are more hydraulically efficient than conventional caps, improving wave attenuation and shoreline / nearshore response for erosion control,

- Better mimic natural benthic and intertidal habitat conditions both in

- Avoidance of unnecessary cap material placement over uncontaminated corners.

Lally has led the development of precision dredging and capping technology and approaches for the remediation of contaminated sediment since the late 1990s. We have guided the development of over 50 different environmental dredges and capping barges, working methods, and hundreds of dredge prisms, target files and capping designs.

Lally LLC offers the following services to assist project owners and contractor’s successfully setup and execute sediment remediation projects;

- 24/7 Worldwide Support

- Procurement Support

- Early Contractor Involvement

- Equipment Mobilization and Startup

- Error Budgets

- Construction Oversight

- Volume and Mass Balance Estimates

- Remediation Design and Construction Training

- Production Estimates and Schedule Analysis

- Dredge Positioning and Automation

- Dredge and Capping Prisms and Target Files

- Performance Optimization

- Residuals Management

- Monitoring Systems

- Environmental Monitoring

- Water Quality Monitoring

- Quality of Life Monitoring

- Quality Assurance / Quality Control

- Pre-, Progress and Post-Dredge and Placement Surveys

- Project Completion Reports

- Acceptance Requests / Contract Management

- Claims Resolution / Expert Litigation Services

As sole-source independent consultant, or member on interdisciplinary team, Lally is often called to serve on projects requiring specialized dredging and/or capping project technology, engineering and environmental expertise. In these capacities Lally LLC has been hired by government agencies, industry clients, engineering firms, environmental consultants, and dredging, marine and soil washing contractors.

Practical Expertise

Slip 4 EAA Sediment Remediation Project Construction Oversight