USEPA New Bedford Harbor Superfund Site

Upper Harbor Cleanup Phase Dredging Program

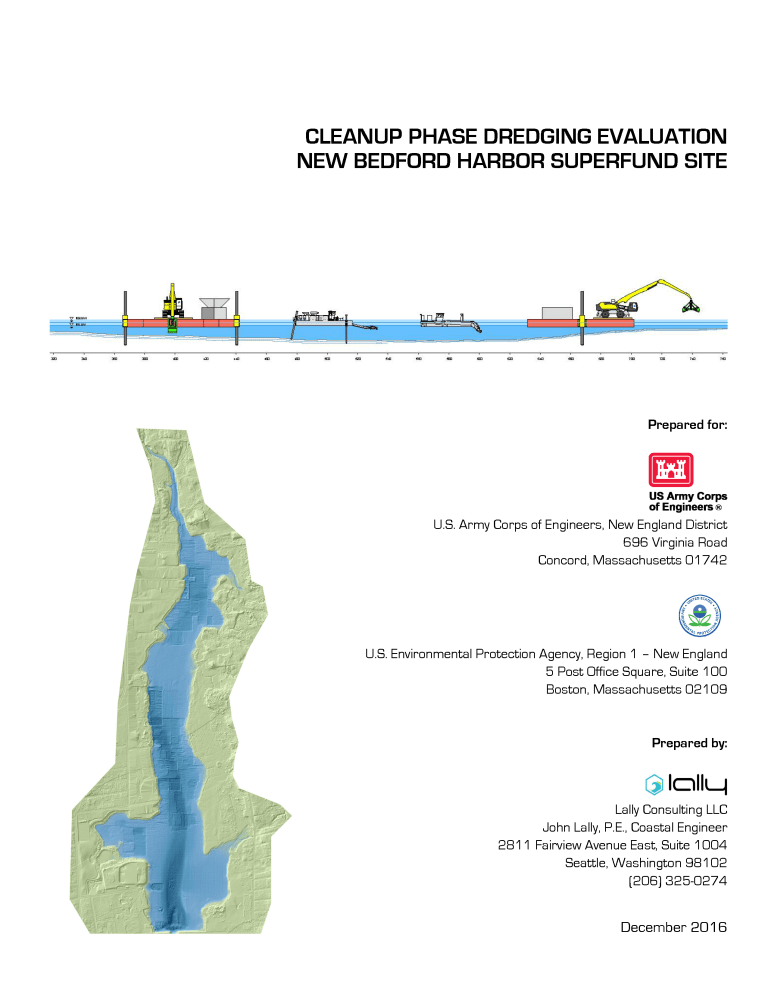

Based on his work performed on the New Bedford Pre-Design Field Test (1998 – 2000) and other USEPA sediment remediation mega-sites since, in 2015 Lally Consulting LLC (Lally LLC) was requested by the U.S. Army Corps of Engineers – New England District (USACE) to provide dredging and sediment remediation expertise to USACE, U.S. Environmental Protection Agency – Region 1 (USEPA) and their multidisciplinary Remedial Action Contract (RAC) Contractor for the cleanup of PCB contaminated sites within the Upper and Lower Harbors of the New Bedford Harbor Superfund Site (NBHSS).

As the NBHSS project progressed toward the cleanup phase, involving the remediation of approximately 200,000 cy of sediment with some concentrations exceeding 3,000 ppm over the remaining 115 acres of Upper Harbor, Lally LLC was tasked by USACE and USEPA under Battelle Professional Services Contract No. W912WJ‐12‐D‐0004 to evaluate the performance of the hydraulic dredging approach employed to date (2004-2015), other alternative dredging and associated sediment management technologies, and provide recommendations for the most technically and cost‐effective approach to complete the remaining work with the limited funds available for the dredging component of the remedy.

Through acquisition and analysis of several data sets over a range of representative site conditions, Lally evaluated the NBHSS current dredging technologies and methods in various categories relevant to the cleanup phase of the project. Per USACE we focused on dredging accuracy, production, residuals generation and release to the water column and air. Potential limitations in hydraulic dredging performance, observed foremost in horizontal and vertical dredging accuracy, and production, were identified which would adversely impact the efficiency and cost to which the remaining NBHSS Upper Harbor subtidal areas achieve target cleanup levels.

To evaluate alternative remedial technologies and approaches effectively, site-wide physical processes and chemical conditions data were assembled and management areas delineated based on bathymetry and tidal range, operational depths, contaminant concentration, contaminant thickness, dredged vs. undredged areas, geotechnical characteristics, shoreline structures and obstructions, habitat, administrative and other factors.

Our recommended approaches were a major shift in the project direction.

Largely based on results achieved during the Pre-Design Field Test (2000), Lally LLC recommended employing hybrid precision excavator with hydraulic transport technology as the primary dredging approach for the remaining NBH Upper Harbor subtidal inventory. A precision excavator with barge transport approach was also recommended to manage areas with heavy debris and / or with lower contamination levels suitable for Lower Harbor CAD Cell disposal. The precision excavator platforms would be convertible, and productive for capping operations as well.

From the analyses and estimates performed in this Upper Harbor subtidal dredging approach evaluation, Lally determined there to be opportunity to save a minimum of $60 million and 1‐2 years in project duration by transitioning from the incumbent hydraulic dredging approach to precision mechanical dredging and design approaches.

In addition to specifying the number, types, sizes and other dredge equipment details for the remaining work and locations, Lally LLC provided recommendations on sediment processing and support equipment, developed production and cost models, and other management and quality control measures to optimally bring the NBHSS Upper Harbor to a successful cleanup.

These recommended technical changes included acquiring confidence in the Upper Harbor contaminant inventory through improved core sampling, analysis, and geostatistical interpolation techniques, upon which more accurate contaminated inventory delineations and volumes can be established. Development of a well thought out project sequencing, within the subtidal areas and integrated with the overall site remediation, confirmatory sampling plan, and post‐dredge backfilling / residuals cover placement approaches were also recommended.

How we Helped

Specific programmatic changes initiated and work completed by Lally LLC included;

- Evaluate incumbent (2004-2015) hydraulic dredging approach for cleanup phase of Upper Harbor project.

- Analyze DREDGEPACK data, daily reports, pre-, progress, and post-dredge survey data, core data, sediment processing and other performance data.

- Conduct webinars with USACE, USEPA and Remedial Action Contractors to present dredge performance evaluation findings and recommendations for full-scale project.

- Developed Conceptual Site Model and Dredge Management Unit Delineation criteria.

- Participated in ongoing Cleanup Strategy and Technical Meetings, on site and remotely.

- Initiate Sediment and Debris Characterization campaigns.

- Guide Equipment Design of precision mechanical-hydraulic dredges, propulsion systems, spud system, and electronic dredge and bucket positioning systems (DBPS).

- Introduce Environmental Bucket Design Modifications, with footprints, kinematics, bowl shape, and venting optimized for the UH subtidal area removal thicknesses.

- Employment of latest generation Electronic Dredge and Bucket Positioning system (DBPS).

- Shallow draft push boat(s) design with optimal configuration to minimize resuspension and residuals, and conduct barge swaps efficiently.

- Introduce Access Dredging design considerations.

- Improve Coring, Analysis and Geostatistical Interpolation (Kriging).

- Shift from depth‐based (DoC) to Elevation‐based (EoC) target definition.

- Lead shift from ‘Z-Block’ (2004–2015) to High Resolution Contour Dredge Prism Design.

- Establish target dredge prism and progress survey matrix files updating frequency.

- Guide more detailed Physical Characterization across a range of variables (i.e. geotechnical, small/large debris, organics) for Mass Balance planning, and More Productive Dredging and Sediment Processing operations.

- Initiate requirement for Specific and Detailed Work Plans to be developed by and confirm understanding of the RAC Contractor performing the work, reviewed and approved by USACE and USEPA prior to Notice to Proceed.

- Develop Performance Standards and other Project Guidance per USEPA and USACE.

- Oversee more in‐depth Quality Control and Quality Assurance programs.

- Introduce and Monitor daily, weekly and monthly performance against Key Performance Metrics, including production, accuracy and confirmatory sampling.

- Adaptive Management based on changing conditions encountered.

- Provide input on Statement of Work Contract Language per USACE.

- Bring to light Engineering and Physical/Chemical processes Data Gaps for remedial design and construction optimizations. Collaborate and Resolve with RAC A/E Contractor.

- Provide guidance on Contaminant Inventory Delineation and SWAC Calculation methodologies for Cleanup Phase, including;

- Introduce understanding of Core Uncertainties and Confidence Intervals

- Data Quality Objectives (i.e core recovery standards)

- Data Gap Sampling Needs

- Curtailing use of Post-dredge data as Pre-Dredge data

- Use of appropriate Geostatistical Interpolation algorithms

- Apply Cross Validation procedures

- Accounting for Intertidal Boundary Effect

- Provide need for and guidance on Vessel Propwash Calculations, and Residuals Management practices to RAC Contractor.

- Review multiple Contractor Work Plans, Quality Control Plans and Long-Term Monitoring Plans. Provide recommendations and guidance as requested by USACE and USEPA.

- Guide Precision Mechanical and Hybrid Dredge Construction, Startup and Ongoing Operations, Prism Design development, and Work Plan details per USACE.

- Provide Electronic Dredge and Bucket Systems, RTK-DGPS and Accuracy guidance to RAC Contractor including number and locations of RTK beacons, sensor number and locations, error budgets and calibration BMPs.

- Provide guidance and education on state-of-practice Precision Dredge technologies to RAC Contractors. Educate RAC Contractors on Precision Dredge Prism Design and DBPS integration.

- Implement 3rd Party Inspection and QA/QC program.

- Dredging Planning and Construction Optimization Meetings, on site and remotely.

The programmatic changes recommended by Lally LLC were supported by the USACE and USEPA. Following completion of this contract, Lally LLC was contracted to oversee implementation of the Cleanup Phase Dredging Design and Construction recommendations and provide ongoing technical support services through completion of the NBHSS subtidal remediation projects under Sole Source Contract W912WJ-18-C-0003.

Services Provided

Project Forensics and Analysis

Conceptual Site Model Development

Evaluate Incumbent Dredge Technology and Methods

Propose and Recommend New Project Dredge Technologies and Methods

Dredge Production Modeling

Cost Models Development and Sensitivity Analysis

Dredge Design Development

Programmatic Sediment Remediation Technical Guidance

Location

New England, USA

Period

2016 – 2017

Lally Consulting LLC received an overall Exceptional rating from the USACE – New England District on its work completed under this contract.