USEPA Superfund Mega-Site

Sediment Remediation Technical Support

Lally Consulting LLC (Lally LLC) has been actively supporting USACE-New England District (USACE) and the U.S. Environmental Protection Agency – Region 1 (USEPA) at several Hazardous, Toxic and Radioactive Waste (HTRW) sites since 2015, with results described by the Government’s project leadership as Exceptional.

Based on its work on other large CERCLA environmental restoration sites in Regions 1, 2 and 10, in 2015 USACE-NAE requested Lally LLC to assist with developing a cleanup strategy for the New Bedford Harbor Superfund Site. Beginning first in late 2015 under Battelle Memorial Institute’s Environmental Consulting Services Contract W912WJ-12-D-0004, then continuing in 2017 under Sole Source Contract W912WJ-18-C-0003, Lally LLC provided dredging and sediment remediation expert services to NAE, USEPA – Region 1 and their contractors for the cleanup of PCB contaminated sites within the Upper, Lower and Outer Harbors of the New Bedford Harbor Superfund Site.

Lally LLC contributions under these contracts, in planning, design, and construction, aimed to establish how New Bedford Harbor Superfund Site project would be completed with optimal benefits to the Government, taxpayers and environment.

Hundreds of work products including dredge and cap equipment designs, sampling and analysis plans for geotechnical and chemical analytical data, dredge and cap prism designs, production and cost estimates, hydrodynamic modeling, propwash modeling, slope stability modeling, advection-diffusion (i.e. CapSim) modeling, calculations, and assorted quality control products using bathymetric surveys, bucket data, and coring data, and other deliverables were prepared by Lally LLC to ensure the CERCLA remediation of New Bedford Harbor was accomplished successfully.

Specific Lally initiatives on the project include;

Precision Dredge / Capping Systems. Through the Upper Harbor Cleanup Phase Dredging Evaluation, detailed analyses of NBHSS site conditions, available remediation technology, production and cost estimates, and other site parameters, Lally recommended and put into effect innovative precision hybrid mechanical-hydraulic dredges, precision mechanical dredges / capping barges, and contour dredging approaches originally piloted on the New Bedford Harbor Superfund Site in 2000 and has developed at other sites. For the NBH full-scale cleanup, Lally determined the number of dredges, bucket sizes, barge advance methodology, other equipment specifications, educated the project team, and established and oversaw the key performance metrics for the project.

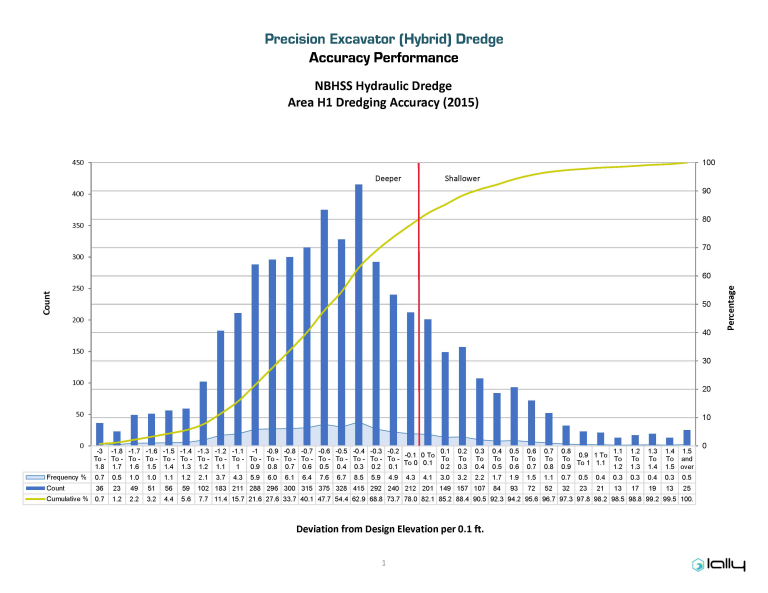

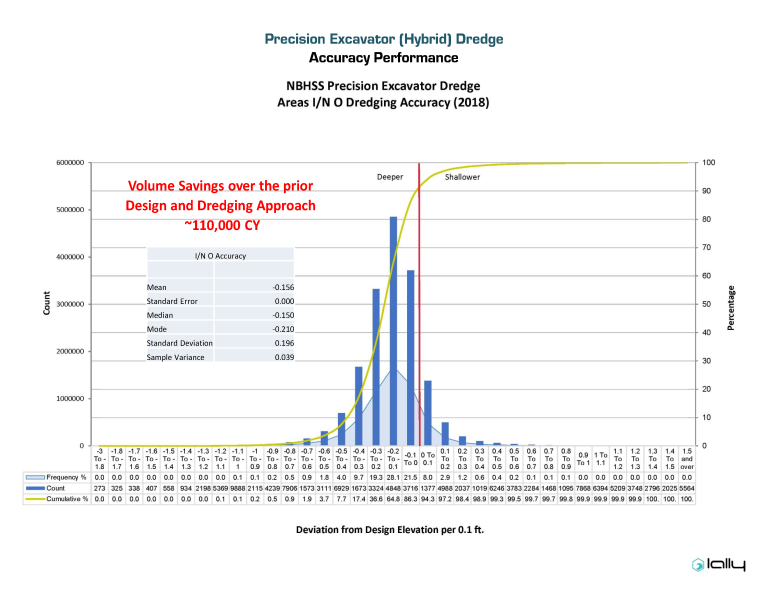

Accuracy. Lally LLC oversaw the development of the NBH’s dredge bucket and positioning system including number and location of RTK- GPS beacons, angle and rotation sensor locations and accuracy, overall positioning error budget, calibration procedures, and software requirements for the dredge and bucket positioning (DBPS). Lally LLC also developed the modifications necessary for the contractor-provided environmental clamshell bucket to be accurate. The realized dredging accuracy for the NBHSS based on Lally LLC’s work averaged 0.15 ft below target, saving the project in excess of 100,000 cy of unnecessary removal of clean sediments. Conversion of the precision mechanical dredges to capping barges for subaqueous cap construction was designed to further provide project savings in the ability to place thin layers with a high degree of accuracy, production and along curvilinear cap boundaries.

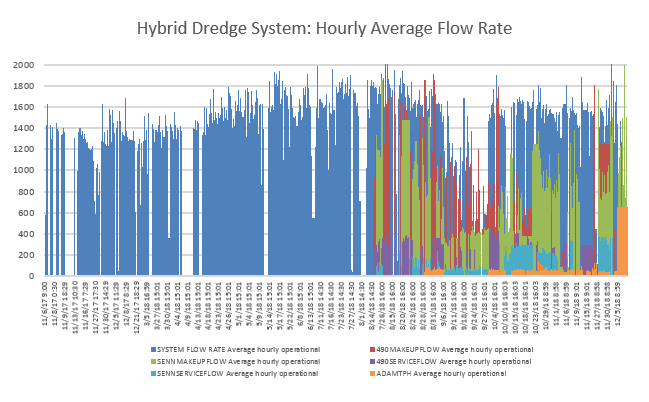

Production. During remedial design phases, Lally LLC instituted for the project improved dredge area physical characterization of geotechnical, small/large debris, and organics for optimized dredging, processing mass balance, and operational efficiency. We further conducted analyses and optimization efforts while monitoring dredge performance on site and remotely to increase production over the duration of project construction, through specific recommendations and education on equipment modifications, including grizzly screen replacement for increased feed rate, debris clearing protocols, effective time monitoring and delay analysis, matching bucket efficiency to dredge cuts, tide-restricted and unrestricted dredge advance, and numerous water management improvements.

Cleanup Efficiency. The precision dredging equipment and methods, dredge prism design, sequencing and lane management, propwash management, cut thickness planning, overlap settings, slope management, and other residuals management approaches instituted by Lally LLC enabled the Upper Harbor subtidal project, with an average pre-dredge concentration of approximately 240 ppm, to attain a final surface weighted average concentration of approximately 3 ppm. Approximately 90% of the harbor achieving this level of cleanup in just one pass. The innovations, methods and optimizations implemented by Lally served to achieve project cleanup standards (10ppm) established by the Record of Decision, and greatly reduce sediment toxicity to stimulate the recovery of various benthic and fish species, flora and fauna and protect human health.

Sampling and Analysis. Lally LLC introduced the concept and understanding of sample core uncertainty on the NBHSS project. To improve core confidence, Lally LLC proposed a specific set of improvements including establishing Data Quality Objectives (DQOs), namely;

- greater sample density,

- minimum core recovery,

- absolute elevations in core tube,

- known sampling methods and accuracy,

- prevention of erroneous normalization of original (pre‐dredge) core sampling depths to the existing (post‐dredge) elevations, and

- application of adequate, but not overly conservative, uncertainty to the core data.

Once these sampling and analysis improvements were adopted on site, geostatistical modeling (Kriging) could then be improved to develop more accurate contaminant inventory delineations and dredge prism designs, which greatly contributed to project cleanup efficiency and production gains.

Quality Control. For quality control during operations, Lally LLC implemented several measures including more intensive progress bathymetric surveys to assess dredging accuracy and update DBPS matrix files, multibeam surveys for dredge accuracy analysis and planning, conducting more intensive and denser verification sampling to inform cleanup efficiency, and development of more detailed and specific contractor work plan submittals to demonstrate project understanding and preparation prior to starting work in an area. Lally LLC’s quality control efforts extended to educating and mentoring the RAC A/E Contractor team on engineering design, quality control, and remedial operations through the work plan development process, weekly conference calls, on site, and other formats.

Upper Harbor Cap Design. At the request of the USACE, Lally LLC authored the project design guidance for the NBHSS caps to be installed at isolated subtidal locations with more complex residual contamination. Lally LLC introduced multi-layer engineered caps as the recommended approach for the contamination levels and hydrodynamic conditions at the locations not conducive for contaminant removal. Lally LLC’s cap guidance document provided functional descriptions of physical isolation, chemical isolation, and erosion control layers, cap materials including active components, design and construction considerations, contaminant flux models, and additional guidance. Lally LLC was requested by USACE / USEPA to develop Krig-derived cap models to ensure a consistent methodology for coverage and isolation. These cap designs were developed for all the site’s permanent subaqueous caps including Crib Cap, O-711, L014, L114, Coggeshall East, Coggeshall West, and Area C Pilot CDF, with modifications to integrate with intertidal excavation and other features (i.e. steep slopes), as necessary.

Hydrodynamic Modeling. With support from Deltares, architect of the DELFT3D numerical modeling system, Lally LLC developed a coupled flow and wave hydrodynamic model of the full New Bedford Harbor estuary using the DELFT3D-Flow and Wave modules. The model simulates the site’s hydrodynamic and sediment transport regime under various storm recurrence interval, bathymetry, and water level conditions. The nested domain consists of three orthogonal curvilinear grids; Buzzards Bay, Lower and Outer Harbor, and Upper Harbor. The validated model was used to assess stable bed particle sizes in support of erosion control layer design for subtidal interim and permanent caps.

LHCC Management. Lally LLC analyzed confined aquatic disposal (CAD) cell bathymetry and volume capacities within the New Bedford Lower Harbor CAD cell complex, proposed various dredged material management and monitoring protocols, and designed confinement berm and sill concepts to optimize utilization of the LHCC. During mechanical dredging with LHCC disposal work plan development and construction operations, Lally LLC stressed the need for CAD cell placement planning, and the ability to place material with an increased level of control. Lally LLC assessed bottom dump placement operations and sill construction approaches proposed by the contractor and imparted higher levels of operational control to optimize cell capacities and avoid slope failures.

Project Savings. By Lally LLC’s initiatives, the NBHSS project has saved in excess of $90 million, and was completed approximately two construction seasons earlier than would have been required by the incumbent dredging and design approaches. Based on the relatively small fees for its 3rd party technical advisory services, Lally LLC achieved a better than 60:1 benefit-cost ratio for the project, that is, for every $100,000 spent on Lally LLC services, the Government saved in excess of $6,000,000, achieved cleanup goals, and maximized remediation on the NBHSS. The savings are now being beneficially used to restore nearshore and intertidal habitat along the project boundaries to further serve the community and the environment.

Services Provided

Comprehensive Sediment Remediation Technical Advisory Services

Implement New Sediment Sampling Program

Implement New Kriging, Dredge Prism Design

Dredging Plans Design

Establish Performance Metrics for Production, Accuracy and Cleanup Efficiency

Dredge Equipment and Operations Optimization

Construction Oversight

Water Management

Contractor Negotiations

Capping Design Support

CAD Cell Planning and Management

Knowledge Sharing, Mentoring

Location

Massachusetts, USA

Period

2017 – 2020

Related Projects

For its work under the sole source contract W912WJ-18-C-0003, Lally Consulting LLC was nominated by the USEPA Region 1 project leadership and selected by an awards panel of EPA representatives from across the Agency as the 2020 (FY 2019) national recipient of the USEPA Administrator’s Award for Outstanding Accomplishments by a Small Business Contractor.